Integrating CAD/CAM Technology into Daily Dental Practice: New Levels of Precision and Efficiency

Classic prosthetics, which rely on silicone impressions, remain pertinent and are widely utilized. However, an increasing number of specialists are turning to digital technologies. These technologies facilitate the process from the diagnostic phase through to the milling of a full-arch prosthesis from a singular block of zirconium dioxide. It is solely through CAD/CAM technologies that patients can visit the clinic and return home on the same day, sporting a new smile.

Best Digital Denture Design Software

A CAD/CAM system encompasses scanners, 3D printers, CNC milling machines, and additional apparatus. However, the core of the system is the software. This software enables the conversion of data from scanners and computed tomography into 3D files, facilitating tasks ranging from planning surgical implant procedures to the development of prostheses. The market offers a plethora of digital dentistry software packages, yet the most acclaimed include:

- CEREC: Provides comprehensive solutions from scanning to production, guaranteeing swift and precise operations.

- Exocad: Renowned for its adaptability and user-friendly interface, it empowers dentists to craft superior digital models.

- 3Shape: Delivers cutting-edge scanning and design tools that are instrumental in achieving superior prosthetic aesthetics and functionality.

These tools are precise and dependable, and the only drawback is the fairly high price. Naturally, prices will vary across different regions and are contingent upon the software’s level and feature set. For an approximate comparison of costs, please refer to the table below.

| Software | Approximate price (USD) | Annual license (USD) |

| CEREC | 30,000 | 3,000 |

| Exocad | 5,000 | 1,500 |

| 3Shape | 10,000 | 2,000 |

Indeed, the initial integration of CAD/CAM technologies necessitates substantial investment. However, this investment subsequently enables the enhancement of service quality and the capacity to serve an unprecedented number of patients.

Advantages of Using CAD/CAM Technologies in Denture Creation

The application of CAD/CAM technologies in dentistry offers numerous benefits:

- Precision and Quality: Digital technology ensures high precision in the design and fabrication of prosthetics, leading to an improved fit and enhanced functionality.

- Speed and Efficiency: The automation of manufacturing processes significantly reduces the time required to produce prosthetics, allowing for the delivery of complete solutions within one or two visits.

- Aesthetics: CAD/CAM technologies facilitate the creation of highly aesthetic prosthetics that seamlessly blend with the patient’s natural teeth.

- Patient Сomfort: Scanning without the use of traditional impressions makes the process more comfortable and less invasive for the patient.

- Cost-Effectiveness: Reducing the time and labor required to manufacture prostheses reduces overall costs for both clinics and patients.

The Significance of Adopting CAD/CAM Technologies in Dental Clinics

Let’s highlight a notable dental clinic in the USA that has embraced digital technologies: CAD/CAM CENTER Miami. This Miami-based center provides an extensive array of digital dentistry solutions, encompassing both equipment and training.

Next, we will succinctly examine a clinical case to gain a deeper understanding of the capabilities afforded by contemporary CAD/CAM technologies, including robotic surgery.

The patient asked to restore severely damaged teeth, please see the picture below.

This clinical case’s distinctiveness lies in the patient’s request for individual implants to restore each tooth in sites 6-10. Conventionally, a splinted design is employed for such scenarios. However, the patient was dissatisfied with the aesthetic outcome of bridgework; she desired a restoration that closely resembled her natural teeth.

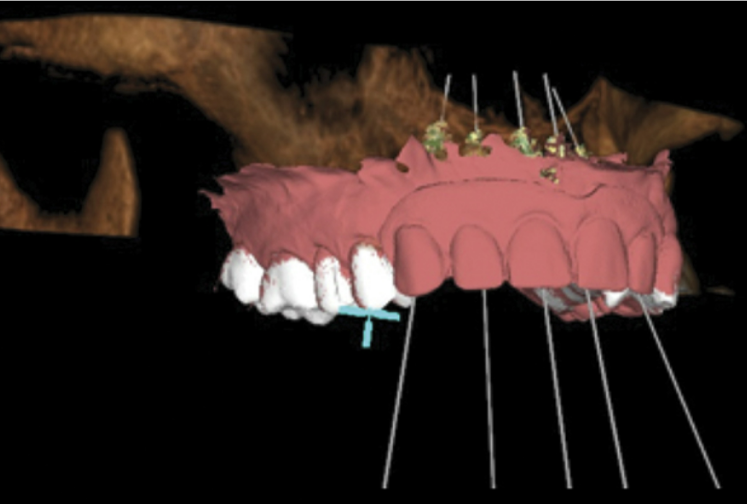

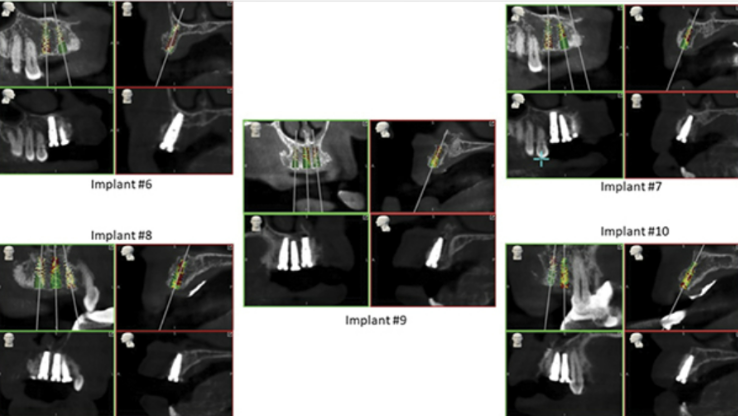

Executing such intricate work necessitates the utilization of digital technologies at every stage. The diagnostic phase comprised multiple scans of the oral cavity using an intraoral scanner, along with Cone Beam Computed Tomography (CBCT) imaging. Special emphasis was placed on accurately depicting the interdental papillae, age-appropriate to the patient, a crucial factor for the aesthetic success of the prosthetics.

A digital treatment plan was formulated, ensuring the optimal positioning of the implants, spaced approximately 3 mm apart. This spacing is critical to preserve an adequate volume of the interproximal bone ridge.

Throughout the design stages, specialists adhered to the guidelines set forth by Dr. Tarnow and other eminent authorities in the field of aesthetic restoration design. The choice was made to employ the Yomi® Dental Robotic System (Neocis), which facilitates the use of reference markers on the day of surgery to verify the precision of implant placement, angulation, and depth.

In anticipation of the surgical intervention, moderate bone grafting and soft tissue augmentation were performed to establish more favorable oral conditions for implant insertion. Subsequently, five implants were precisely placed in the upper jaw’s aesthetic zone.

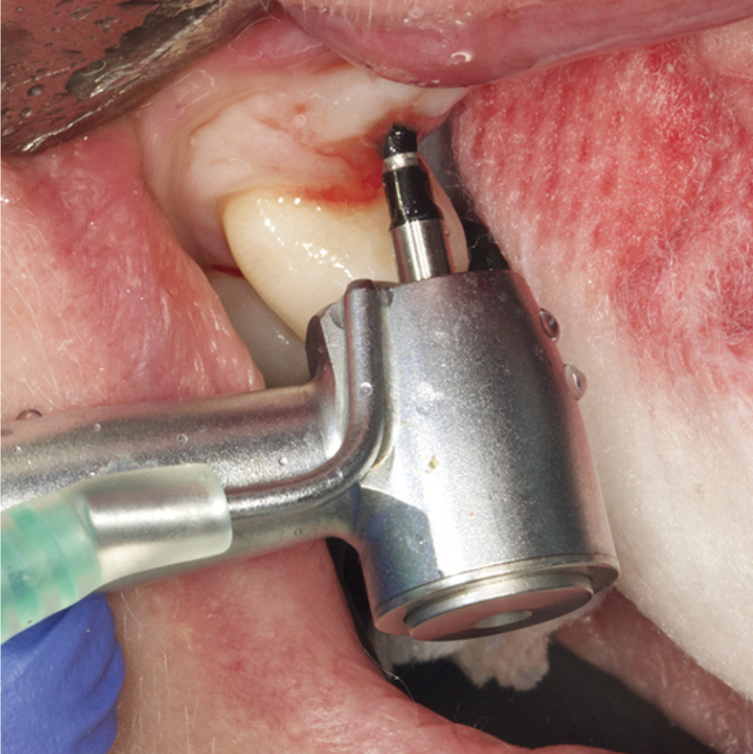

Implant placement using haptic robotic guidance. As osteotomies are prepared, the robotic arm locks the handpiece at the correct spatial position both in bodily direction and angulation, and as the clinician drills to proper depth, the arm prohibits further drilling apically

The implant placement procedure was entirely flapless, which significantly reduced invasiveness and facilitated rapid healing of the patient’s soft tissues. The surgeon, exercising full command over the robot, navigated the arm to the designated implant sites. During this process, the surgeon assessed the emerging soft tissue type, evaluated bone quality, and ensured adherence to the preoperative plan by intraoperatively verifying the robotic system’s accuracy. Real-time audio and visual updates confirmed that the clinical parameters had been successfully achieved.

Following the implant placement, the patient was equipped with a temporary prosthesis. This provisional solution was utilized for four months, during which the osseointegration process of all implants reached completion The surgical phase concluded successfully, inclusive of bone tissue augmentation, providing the orthodontist with a solid foundation for the permanent prostheses. Five milled ceramic crowns, designed for screw retention, were fabricated. The prostheses were adeptly placed, culminating in an outstanding aesthetic outcome (please see the picture below).

Without the application of CAD/CAM technologies, achieving successful prosthetics that align with patient preferences would be challenging, if not impossible, or the outcomes would be markedly inferior.

The incorporation of CAD/CAM technology into routine dental practice unveils new possibilities for both dentists and patients, ensuring superior quality, enhanced comfort, and cost-efficiency. With ongoing technological advancements, the future of digital dentistry is poised to be even more remarkable.

References

Aegis Dental Network: Compendium of Continuing Education in Dentistry – Digital Technology Redefining Implant Therapies: Two Case Reports – January 2022