All abutments are made of titanium-aluminum-vanadium alloy – Grade 23 (Al6 -4V). This alloy is close in strength to the popular Grade 5 alloy, practically not inferior to it in strength (828 MPa – Grade 23 and 860 MPa – Grade 5). But Grade 23 is superior to Grade 5 in elasticity. Elasticity is more important when fabricating thin parts of abutments, screws and implants.

Our technological process is built in such a way that tolerances (permissible dimensional deviations) are minimal. This is confirmed by laboratory measurements.

Straight abutments

We sell straight abutments made of medical titanium, both for a conical connection platform with an angle of 22 °, and for a standard hexagon.

The description of each straight abutment includes the screw type and compatibility with other well-known dental implant platforms.

Please, pay attention to the marking; it describes not only the diameter and total height of the product, but also the height of the shoulder for contact with the gingiva. Let’s consider the following example: Straight Abutment D5mm, H7mm, GH1mm, for Osstem TS3 regular®, see photo below. This particular model has a “low skirt” for cases when the implant is installed high enough (almost at the level of the gums). The height of the taper to the crown support skirt is marked with GH and in this case is 1 mm. This is not enough; usually this figure is in the range of 3-5 mm.

In addition to classic straight abutments, we sell anatomical straight abutments, see photo below.

As for the size range, our website offers straight abutments with a platform diameter:

- 4,5 mm;

- 5,0 mm;

- 5,5 mm;

- 6,0 mm.

Below are height options for straight abutments of our production (note that it is the height GH that is displayed in the filter):

- 1 mm;

- 2 mm;

- 3 mm;

- 4 mm;

- 5 mm;

- 9 mm;

- 11 mm.

The website contains convenient filters where you can select the size and platform of compatibility.

ATTENTION! Delivery of any order from our website to anywhere in the world is for free of charge!

Angled abutments

Angled abutments are required to compensate for the inclination of the dentition relative to the root implant. Sometimes abutment bridges are fixed on a combination of straight and angled abutments. In addition to the standard models, we have a laboratory where custom abutments can be ordered. We sell angled abutments made of medical titanium with angulations:

You can order angled abutments for a standard hexagon or a 22 ° taper through our website. In addition, the following forms are available: standard, anatomical, leaf-shaped and narrow ones.

Healing abutments for dental implants

The healing abutment is placed into the native bone after implantation. Its shape is selected in such a way that the gum shall create a socket during healing, into which a permanent abutment with a crown will fit exactly. The healing cap is removed 3-6 months after the installation of the root implant once the osteo-integration process is completed.

We sell healing caps of the following diameters:

- 3,5 mm;

- 4,0 mm;

- 4,5 mm;

- 4,6 mm;

- 5,0 mm;

- 5,5 mm;

- 6,0 mm;

- 6,3 mm;

- 7,0 mm.

Below are available height options for healing abutments:

- 2 mm;

- 3 mm;

- 4 mm;

- 5 mm;

- 6 mm;

- 7 mm.

This group of products, like all others, is also subject to the condition of free shipping anywhere in the world.

Screws for securing abutments in dental implants

Abutment screws are a simple but crucial element. After all, most cases of loosening and loss of the abutment are interrelated. The screw for the abutment must withstand significant tensile strength, compressive and torsional stresses and loads. In addition, the accuracy of the thread pitch and the execution of all grooves are extremely important when manufacturing screws. Therefore, we can proudly say that our abutment screws are not only on par with the world’s leading counterparts, but often superior.

Why is it safe to buy abutments and other components manufactured by our company?

Many professionals are wary of the use of third-party abutments and other components. There is some common sense in this, because every dentist wants to reduce the risk of problems. Therefore, we made a detailed analysis of the most common problems with a description of how much this or that problem is related to the quality of the abutment, screw or the root implant itself. Looking ahead, the most frequent reason of arising problems is the patient’s clinical condition, such as bone deficiency or bone poor quality as well as the patient’s dismissive attitude to hygiene and preventive examinations.

The second reason is implantation with violation of the protocol and lastly, there are problems with the low quality of the implant itself, abutments, etc. However, here is our detailed analysis.

- The implant does not take root. We are talking about the first three months after implantation. Loss of an implant one year or more years later already refers to the problem of implant failure. Some of the reasons are:- Installation of an implant with a noticeable bone deficiency, in order to speed up the process and avoid bone augmentation (bone grafting). The quality of the root implants and abutments has nothing to do with it.

– A worn out or poor quality tool was used to create the socket in the bone or there was a violation of the cooling protocol because overheating of the bone leads to necrosis and loss of the implant. This reason also has nothing to do with the quality of the abutment and the implant itself.

– Wrong positioning of the implant, for example, beside the central part of the alveolar ridge. It does not happen very often, but it is included in the statistics of the reasons;

– Incorrect treatment plan, i.e. lack of interaction between the orthodontist, dental technician and surgeon might result in implant failure.

– Incorrect calculation of the length and diameter of the implant during the simultaneous restoration of the dentition in the cosmetic zone. Again, all the complaints about this issue do not relate to the manufacturer of root implants and implant abutments.

– The material was of poor quality, as well as the design of the implant itself. Fragments of a poor-quality alloy migrate into the bone, causing fibrous degeneration and, as a result, the loss of the implant. Here, the reason is 100% poor-quality implant. Thus, it is better not to save money and install only proven platforms of dental prosthetics.As you can see, in most cases, the quality of implants, angled screws and abutments does not affect engraftment. Please note that 98-99% of implants take root and all of the above is 1-2% of the total. This means that we can summarize that a good result can be achieved with almost any dental implantation platform, the choice depends on the clinical picture and the experience of using a particular system by a particular specialist.

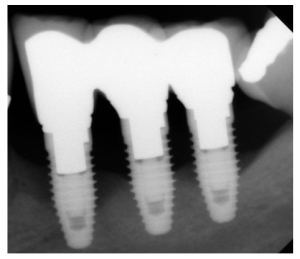

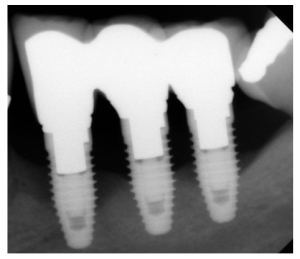

- The dental implant failure. We are talking about the loss of already engrafted implants, most often as a result of an inflammatory process. The inflammatory process can be caused by poor hygiene on the part of the patient, as well as overload and overexertion caused by defects in straight and angled abutments along with incorrect placement of a crown or bridge. Let’s take a closer look at the reasons for the implant failures:- There might be high tolerances while manufacturing abutments. For example, one set of straight abutments with a diameter of 3.5 mm, may have a variation from 3.41 to 3.58 mm. The same variation can be applied to the height. Therefore, if the dentition needs to be restored, then the bridge will be skewed and overstrained. After all, the dental technician took into consideration the exact dimensions of the abutments, but in fact, we can observe steps. You cannot see such a difference by eye, but after a year or two the internal stress of the prostheses will be transferred to the place of contact of the implant with the bone. A root implant is not a living tooth and it does not have such mobility and ability to compensate for axial and lateral loads. Over time, pathological pockets develop at the place of contact between the implant and the bone, and as a result the inflammatory process begins, which develops into peri-implant pathology. That is why in our company special attention is paid to the accuracy of manufacturing of all parts. In our practice, tolerances of hundreds and even tens of microns are unacceptable.

– Placement of implants next to inclined teeth. Such a situation may happen when teeth were lost many years ago, and as a result adjacent teeth tilt and shift.

In addition, orthodontic treatment has to be done before the implantation. Otherwise, a triangle develops between the crown and the inclined tooth, where food debris is clogged. This is a zone of risk and permanent inflammation, which over time can provoke peri-implant pathology. The risk of inflammation is especially high in cases of bone deficiency. In such cases peri-implant pockets easily develop, which are difficult to clean and practise good hygiene.

– Incorrect placement of the dental prostheses. We described a similar problem above, when the implant is installed not in the center of the alveolar ridge and not even under the future restoration of the dentition, but a little to the side. Such dental prostheses may well take root, but when installing a crown or bridge, it turns out that the implant is loaded only from the side, even with an axial load of the jaw. In this case, overexertion also occurs, and the risk of inflammation and loss of the implant increases.

– Insufficient care and neglect of oral hygiene on the part of the patient. Even if the orthopedic surgeon did everything perfectly and the implants took root, inadequate care and cleaning can lead to chronic build-up of food debris around the abutment neck. This means the likelihood of persistent inflammation and the risk of peri-implant pathology. Many patients simply ignore professional cleaning and preventive examinations.

– Bad habits of the patient, namely smoking. The components of tobacco smoke cause vasospasm in the oral cavity, and, as a result, a deterioration in the nutrition of the gums. It goes down, pockets are formed, where, again, food debris accumulates and pathogenic microorganisms multiply.As we can see, in the long term, both the experience and qualifications of a specialist and the product quality are important, and the main criterion for quality is the accuracy of manufacturing and the high quality of surface treatment of the abutments. In our company, special emphasis is placed on accuracy of manufacturing and compatibility in thread pitch as well as taper accuracy and other aspects that affect compatibility and durability. For example, if you have to replace a crown with an angled or straight abutment after five years, then you will buy parts from us exactly the same size as you already had. And the new restoration will fit perfectly, without distortions and internal overexertion.

- Abutment loosening. The most common reason is the gaps and inaccuracies in the process of manufacturing abutments and retaining screws, which we have already mentioned. It is also very bad if the gap between the implant and the abutment contains biofilm (a film with microorganisms). Therefore, quality control over accuracy and minimum tolerances is the primary task of our company. We are free from bureaucracy and a large office apparatus, but as to production and quality control, we are not inferior, and in some cases even surpass the best manufacturers of platforms for dental implantation.

- Fracture of the abutment with the crown or bridge. Such a situation may be due to patient injury from being involved in an accident or fighting. The same is true for some of the reasons already mentioned: positioning errors or large tolerances. In such cases, an urgent replacement of the abutment is needed (sometimes replacement of the implant), which means that your supplier should have a warehouse at least in the United States, and at most in your city.

- Chipping of the crown. The reason may include manufacturing errors, and as a result, an abnormal bite with overstrain or a dental bridge may be too long. In addition, individual peculiarities of the patient may be the reason for crown chipping, namely, bruxism or a patient simply tried to bite through something solid, even knowing that it was forbidden. Minor chips can be restored using the same methods as filling a regular tooth, but in case of serious problems, you will have to change the crown, and sometimes buy a new abutment. For this reason, it is critically important that an identical abutment can be ordered without problems and received in the shortest possible time. Therefore, a round-the-clock opportunity to place an order (at least online) and receive an abutment as soon as possible (2-5 days) is important.

- Separation of the cementing layer and loss of a crown or bridge. It can also be caused by an error or poor-quality cementing mix, as well as unforeseen circumstances such as injuries the patient sustained. In this case, it is desirable to have an adequate supply of all types of abutments, screws and root implants or have a reliable supplier who can quickly resolve the issue of delivery of the necessary parts for dental implantation.

Why is it profitable for dentists to work with us?

All our resources are aimed at producing high-quality and popular products for dental implantation. Abutments of all types are perhaps the most demanded element after the initial installation of a root implant.

Thus, more and more specialists in dentistry and dental prosthetics choose our company because:

- You pay only for the quality and only for the product. We are considered to be a lean company. We do not have a large staff of marketers, agents, public relations specialists. After all, if you buy abutments from another brand, you understand that the price includes the salaries and taxes of a huge staff of office workers, whose work does not affect the quality of products in any way. We have a fair price for abutments, and you always know that our abutments are the best you can find for this money.

- We do not force you to buy large volumes and freeze money by investing in implants and spare parts for them. You can order a minimum batch from us (you need to mention if there are restrictions from one piece, or from $ 20), and we will deliver your order for free to anywhere in the world.

- In addition, we have a warehouse in the United States, so the order will be delivered in the shortest time possible.

If you want to receive samples for testing, please, send us a request, and we will contact you shortly.