In this section, you can buy abutment screws for both straight and angled abutments made from strong and flexible Grade 23 titanium alloy, which is comparable in strength to Grade 5 but superior in plasticity. This is a critical parameter, since dental abutment screws are subjected to bending and tensile stresses. Clinical abutment screws are used for fixation to the implant in the patient’s mouth. This is a small but critical detail as a mistake in selection can lead to unscrewing and breakage of the screw. Note that the markings and names of screw retainers are not standardized. Abutment screws are called:

Key properties of abutment screws

The screw connection between implant and abutment must be strong and secure. After all, the denture works under considerable and, most difficult of all, multidirectional loads. The axial and lateral loads are particularly challenging in the case of single implants. This is where screw loosening is most common.

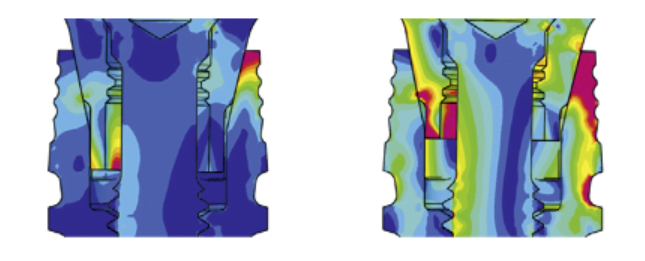

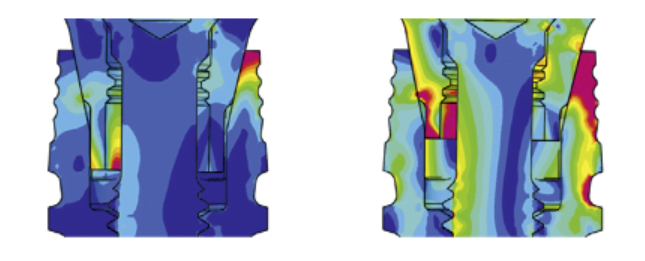

It is essential to buy abutment screws that are 100% designed for a specific platform. Most implant manufacturers recommend using only their own screws and abutments. This is the only way to guarantee a good result of the restoration. This makes sense as the image below shows the load distribution for a brand-name suprastructure (left) and a combination of an implant from one manufacturer and a screw and abutment from a third-party manufacturer (right).

The yellow and red gradations depict point overloads and show that the accuracy of the third-party parts leaves a lot to be desired.

Unfortunately, third-party screws and abutments very often have dimensional deviations that cannot be detected by the naked eye. This can lead to bending and uneven load distribution in the implant-abutment fixture. Remember, fit and twist does not always mean it works well. With the wrong choice, the risk of screw loosening or breakage increases. If you do break a screw, we have an article on our portal that makes recommendations for removing the broken screw without complications.

In fact, alternative abutment screws can be used, but they must be 100% compatible.

It is important to understand that the slightest deviation in thread pitch and coil angles will result in improper adhesion. It is impossible to detect such a problem at the stage of dental abutment placement and subsequent prosthetics. On our site, the screws are 100% compatible with the specified platform.

Our company’s approach differs from most other manufacturers of prosthetic components. The main emphasis at Uniqa Dental is placed on the accuracy class of equipment and staff qualification to minimize tolerances (deviations) in the production of parts. Far less effort and resources are spent on marketing. If you decide to buy our implant parts you will get the highest level of precision and quality, but you will not see beautiful brochures devoid of useful information.

IMPORTANT! All clinical components, screws, abutments, etc. are supplied non-sterile. For clinical use, pre-sterilization is required according to standard procedures.

Causes of abutment screw loosening in implants

- Use of laboratory screws instead of clinical ones. They are not meant to be used all the time and do not provide the desired grip in the long run.

- Violation of the high-precision fit of the abutment and screw. Often this is due to too large tolerances in the size of the elements, sometimes up to 50-100 microns, which is a lot for high-precision parts.

- Use of non-regulatory tools. All wrenches and auxiliary tools must be suitable for a specific platform and a specific screw.

- Use of elements that are not fully compatible. Even slight mismatches in thread pitch and height can lead to problems notwithstanding that the screw will spin and may even show the necessary torque.

- Elementary marriage of the interface – abutment or screw. The phenomenon is extremely rare, but still happens with all manufacturers.

- Installation errors. For example, violation of the protocol after the initial puff, you should wait 10-15minutes before again applying force with a torque wrench. In many cases it is possible to tighten the screw a little more. The fact is that after the initial fixation, the screw is stretched and the adhesion of the threads is somewhat weakened.

Why buy abutment screws through Uniqa Dental?

All of our resources are focused on the production of quality and demanded products for dental implants. Screws compatible with attachment: internal hexagon and 22° and 24° taper. Remember the price of a quality screw is negligible in terms of prosthetic surgery and the problems associated with unscrewing and breaking the screw will be very expensive.

So, why do dentists choose to work with Uniqa Dental?

- They only pay for the quality of the product. We are a lean company. We do not have a large staff of marketers, agents and public relations specialists. If you buy a different brand of screws, the price includes the salaries and taxes of a huge staff of office workers, whose work has no effect on the quality of the product. We have a fair price for proprietary screws, and you always know that our components are the best you can find for the money.

- We don’t require you to buy large quantities and freeze your money investing in implants and implant parts. You can order as little as one unit of any item from us. We ship your order completely free of charge anywhere in the world.

- In addition, we have a warehouse in the USA, so your order will be delivered in the shortest possible time.

If you would like to get samples for testing, send a request and we will get back to you shortly.