Comparison of Implant/Abutment Connection Types

In this article, we will analyze the differences and advantages of the most popular types of internal implant-abutment connections. Let’s take a closer look at the internal hexagon and the cone with platform switching. We will also get acquainted with promising new products such as slotted connections between an implant and an abutment.

How are friction joints different from sliding joints?

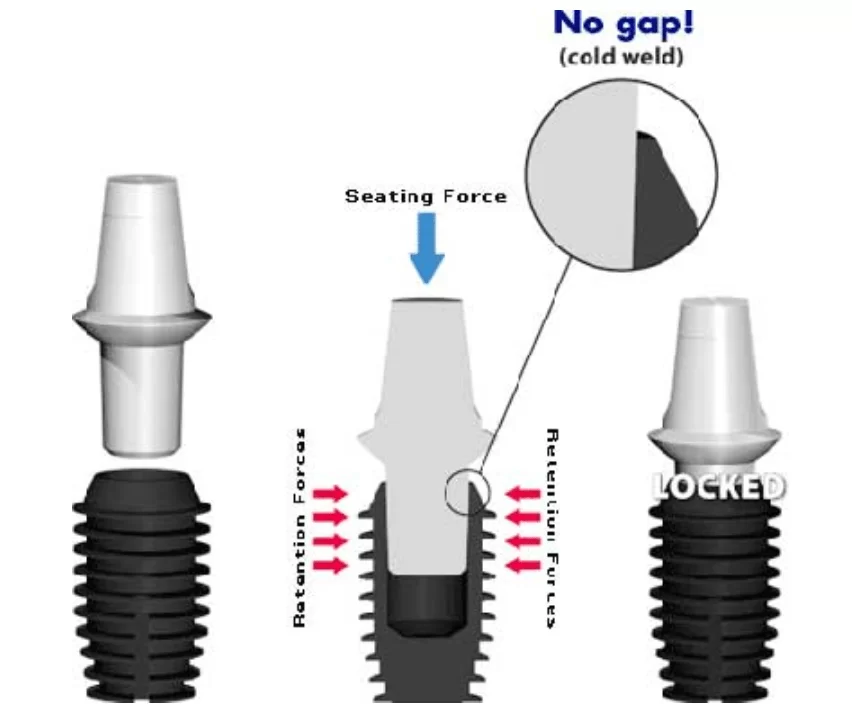

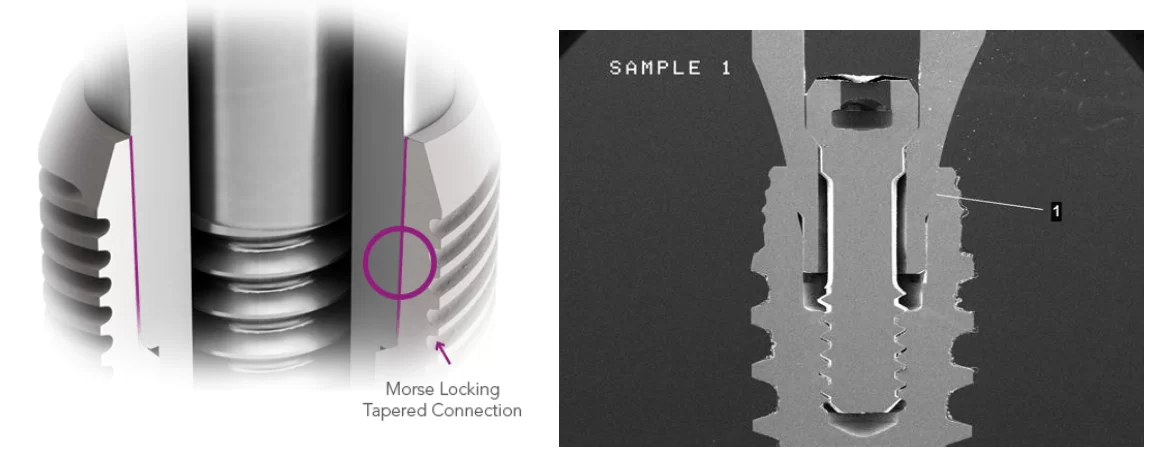

Specialists differentiate friction and sliding types of connections. The key difference in the density of the connection is the presence of a gap between the surface of the abutment and the socket. Friction connections are positioned as wedged. That is, they create an extremely tight joint at the level of cold welding. This type of connection should not allow biological fluids to pass through the connection, and really good results have been achieved. An example is shown in the picture below, which shows that the gap is not visible at all at the junction.

Manufacturers of conical connections especially emphasize the tightness, and this is confirmed in a number of studies, see the following list:

- Mairgünther R, Nentwig GH. Das Dichtigkeitsverhalten des Verbindungssystems beim zweiphasigen Ankylos-Implantat. (The tightness behavior of the connection system of the 2-phase Ankylos implant). Z. Zahnärztl. Implantol. 1992; V:50-53.

- Erfassung, Ursachen und Folgen von Mikrobewegungen am Implantat-Abutment-Interface Zipprich, Holger / Weigl, Paul / Lange, Bodo / Lauer, Hans-Christoph Implantologie 15 (2007), Nr. 1

- In vitro evaluation of the implant-abutment bacterial seal: the locking taper system. Dibart S, Warbington M, Su MF, Skobe Z. Int J Oral Maxillofac Implants. 2005 Sep-Oct;20(5):732-7

The Morse taper principle is used in many technical solutions. For example, a high pressure valve. If such a connection is airtight and capable of holding gases and liquids under high pressure, then it should also hold saliva with microbiota. There are, however, other studies that do not confirm this:

- Clin Oral Implants Res. 2010 Mar; 21(3):328-35. doi: 10.1111/j.1600-0501.2009.01837.x. Epub 2010 Jan 13. Microbial leakage through the implant-abutment interface of Morse taper implants in vitro. Aloise JP, Curcio R, Laporta MZ, Rossi L, da Silva AM, Rapoport A

- J Periodontol. 2012 Apr; 83(4):491-7. doi: 10.1902/jop.2011.110320. Epub 2011 Jul 22. Bacterial leakage in implants with different implant-abutment connections: an in vitro study. Assenza B, Tripodi D, Scarano A, Perrotti V, Piattelli A, Iezzi G, D’Ercole S.

- Implant Dent. 2012 Aug; 21(4):335-9. doi: 10.1097/ID.0b013e31825cd472.

An in vitro investigation concerning the bacterial leakage at implants with internal hexagon and Morse taper implant-abutment connections. Tripodi D, Vantaggiato G, Scarano A, Perrotti V, Piattelli A, Iezzi G, DʼErcole S. - Int J Oral Maxillofac Implants. 2012 May-Jun; 27(3):551-60 Leakage of saliva through the implant-abutment interface: in vitro evaluation of three different implant connections under unloaded and loaded conditions. do Nascimento C, Miani PK, Pedrazzi V, Gonçalves RB, Ribeiro RF, Faria AC, Macedo AP, de Albuquerque RF Jr.

It was reliably established that micro leaks in conical joints are minimal, and even less compared to another popular type of friction joint – an internal hexagon, but the difference is not as significant as marketers say.

Sliding joints do not form such tight joints, but they have other advantages, such as a more even distribution of the load along the entire length of the implant as well as some others that will be discussed later.

Hexagon – advantages and varieties

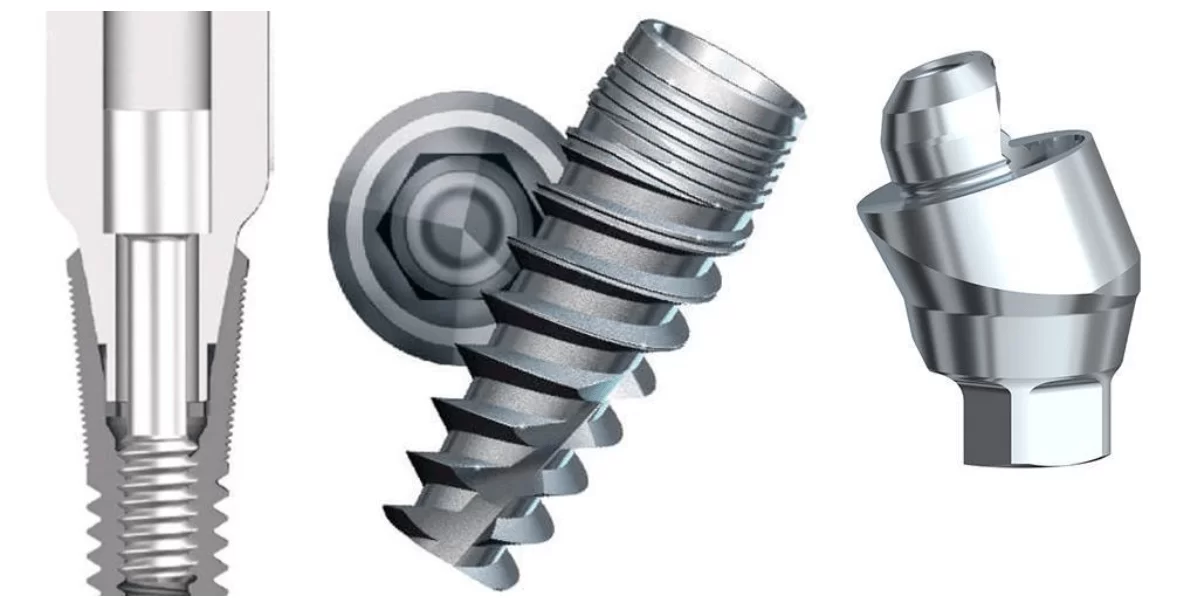

First, let’s take a look at the standard 1.5 mm deep hex connection that many manufacturers use:

- UNIQA Dental;

- MIS;

- Zimmer;

- BioHorizons ;

- XGate Dental;

- AlphaBio;

- Adin;

- AB; and

- Cortex.

This design was developed in the 1980s. Zimmer was the first to use this compound on a large scale and continues to successfully use it to this day. Other companies are also free to use this interface without restrictions.

In 1996, Binon and McHugh did a series of studies and found that rotational mismatch at 30 Ncm torque was 0°. A picture using a scanning electron microscope showed that the implant/abutment transition area is almost monolithic. That is, the same effect of cold welding was achieved.

This excellent result is overshadowed only by the fact that not all manufacturers manage to achieve the required precision in manufacturing parts. Due to too large tolerances in the manufacturing process, not every pair of implant abutment can demonstrate such a connection quality. Therefore, when choosing a supplier of implants and abutments, you should take into consideration the technical characteristics and maximum tolerances. For example, NIQA Dental has a maximum tolerance of ±0.02 mm, and this is a good indicator if your current manufacturer has a worse indicator, you should think about switching to a platform from another manufacturer.

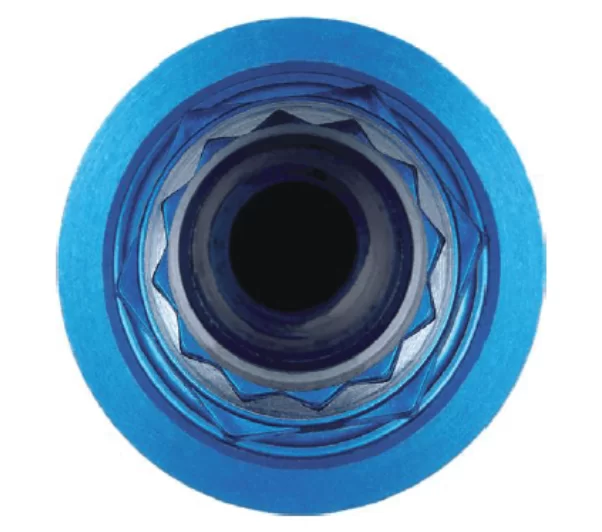

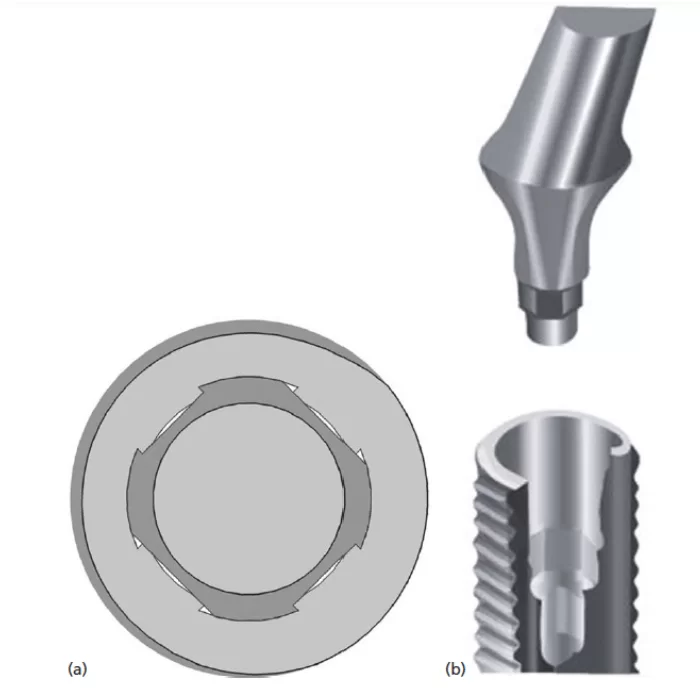

Another interesting solution is used by Biomet 3i: Osseotite Certain™ – this interface has both a hex and a dodecahedral anti-rotation connection, see illustration below.

The 12-way connection is deeper than the hex (4mm) and also has a smaller size and is intended only for angled abutments. A straight abutment sits in a hexagonal interface as in the manufacturers described above, and a 12-sided one is needed so that the specialist can more accurately position the angled implant, because a step of 30 ° is available to him. The correct position of the abutment is accompanied by a distinct click, which facilitates the work of the dentist.

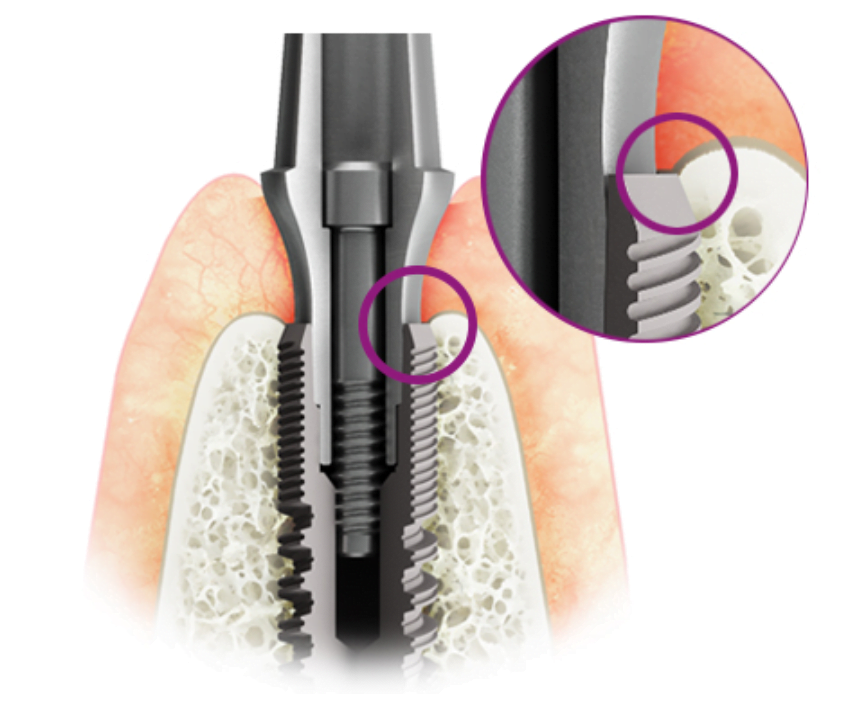

Another feature of Biomet 3i is platform switching. That is, a step between the top of the implant and the abutment. This design is a hallmark of all conical interfaces. Among the hexagonal platforms, only the Biomet 3i has platform switching. True, you will have to pay for this with a large amount of surgical intervention when installing the implant, because the upper end of the implant is wider compared to implants from other manufacturers with the same length and thread diameter.

Morse taper and its varieties

The essence of the interface is the tight connection of two perfectly fitted cones nested in each other. A socket (cone seat) is prepared in the implant, and the abutment has a conical base, which is tightly installed in the implant seat. There is a division into a true Morse taper, and a screw-retained taper connection.

A true Morse taper is held together by friction alone. To date, only Bicon uses this approach. This interface is a 1.5° low-angle conical connection that installs with a noticeable amount of force, but does not require additional screw fixation.

The advantage of screwless fixation is the ability to install the crown in any position in a 360° circle. However, to work with this platform, the dentist must undergo a special training course to be sure of the reliability of the fixation.

Cone interfaces with screw fixation and an angle of 11° are much more common. This interface is considered standard and parts from different manufacturers can be used together with implants or abutments from other manufacturers that support this interface, for example, there is complete interchangeability between brands:

- UNIQA Dental;

- Hiossen;

- Osstem;

- Nobel Biocare;

- Magagen Any Ridge;

- Megagen Any One.

All variants of conical platforms have platform switching. Physically, this is a step between the upper edge of the implant and the base of the abutment.

This technical solution gives a real advantage. Due to the step, an additional space of 1.1-1.3 mm is created for the formation of soft tissue attachment, namely, the level of connective tissues. Collagen fibers form a cuff around the implant. If the implant is placed at the level or even below the bone crest, then ring resorption of bone tissue around the implant is inevitable. The body makes room for the formation of the gingival cuff. Switching platforms due to the step allows a reduction in bone resorption by 0.7-1 mm. However, platform switching works only if the initial thickness of the soft tissues above the alveolar ridge is more than 2.5 mm. With a thin layer of soft tissues, the resorption of soft tissues is the same as with the use of implants with an internal hexagon.

The illustration above shows a classic interface with a cone and screw fixation. There are other varieties as well. Most often, the differences relate to additional anti-rotation elements below the conical part of the abutment, but there are also differences in the angles of the cones. As for the anti-rotation element, most often there is a hexagon, as in the illustration below.

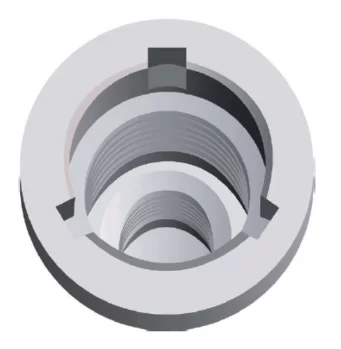

There are other options as well. For example, an octagonal anti-rotation element from Straumann, see illustration below.

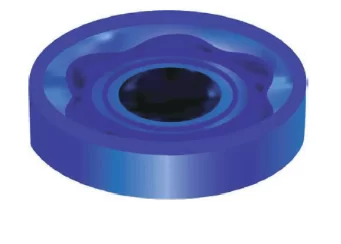

The angle of the cone is also different, here it is 8°. Astra’s taper matches the 11° standard, but the anti-rotation element is dodecahedral. Ankylos also offers an interesting solution. They also have their own signature taper angle of 5.8°, and there are two versions of the abutment with and without slotted guides, see illustration below.

The smooth version is particularly useful for angled abutments because the abutment can be positioned arbitrarily in a 360° circle.

Sliding joints features and benefits

Sliding joints are less common, and most of them are more expensive than the options mentioned above. Nevertheless they are interesting and have their own advantages, see the table below.

Despite the diversity, the most common and in demand are two types of connections – an internal hexagon 1.5 mm deep, and an 11 ° cone with screw fixation. Note also that most manufacturers support multiple platforms with different interfaces. So you need to choose based on the clinical case and the successful experience of using a particular platform. You can get a good result with any platform that is FDA approved.

We hope the material in this article was useful for you. If you want to get a trial kit from UNIQA Dental for $0.99 or $9.99, please let us know in any way convenient for you.