In this section you can buy elements for the dental laboratory. These are components for creating impressions of the jaw, molded abutments for creating crowns, as well as analogues of abutments on which the crown or bridge is attached at the stage of fitting and adjustment on the impression of the jaw. All UNIQA DENTAL products undergo several levels of control and are manufactured using the best equipment available in the world. The company is continuously engaged in research and development, as well as improving production lines to reduce costs. While reducing production costs, product quality doesn’t just stay the same; with each new upgrade, manufacturing accuracy and performance improve. Let’s take a closer look at exactly what you can order through this section.

Transfers for taking impressions

The work with transfers begins with the creation of a jaw impression. This allows you to get a three-dimensional picture of the location of the preserved teeth, as well as the exact positioning of dental implants, taking into account the angle of inclination.

Here you can buy transfers to work with both open and closed tray (spoon). Each option has its own advantages and disadvantages. Let’s break it down a bit more. In both cases, transfers are screwed into an already implanted dental implant. Here is a brief algorithm:

- Remove the gum shaper (healing cap).

- Install the transfer. If it is a transfer for a closed tray, you need to close the shaft of the screw with a special cover (cap). Because the transfer and the cap will be completely filled with polyester or silicone mass. If an open tray transfer is used, caps are not necessary.

- Take an x-ray to make sure that the transfer interface is correctly positioned in the dental implant.

- Place the tray with the plastic material in the patient’s mouth and wait for the material to polymerize.

- Remove the tray with the impression from the patient’s mouth. If surgery was performed with a closed tray, the transfers remain attached to the dental implants, only the cap remains in the impression. The transfers are removed after the impression is removed from the oral cavity and then placed in the impression where the cavities are formed.

If the work was done with an open tray, it is necessary to unscrew the screws fixing the transfers. The screw shanks remain accessible and come out on the back side of the impression. The impression is then removed from the mouth with the transfers remaining in the impression.

In the final stages of both techniques, the gingiva shapers are put in place.

The open tray impression method allows you to obtain a more accurate model, taking into account the angles and position of the implant. But the long shanks of the fixation screws do not allow this method to be used if the implants are placed in the distal parts of the jaw.

The primary impression is a mirror image of the jaw anatomy. A model is cast in the laboratory of the dental technician based on the impression, on which the abutments can be fitted and the crowns can be fitted. During transfer, transfers fulfill another function: the implant analogue is attached to it. If the impression was taken without defects and inaccuracies, the implant analogue on the cast model is in the same place and at the same angle as the real implant in the patient’s mouth.

In the dental laboratory, the casted jaw model allows the technician to use it to fit a single crown or bridge.

The jaw impression can be taken either from the implant level (in the vast majority of cases) or from the level of the abutment. The fact that the impression is often taken from the implant level is due to the fact that it is easier to find a perfect-fitting abutment on the model than in the oral cavity of the patient.

The finished jaw model is checked for defects and inaccuracies. If any are found, the procedure is repeated.

Transfer molds are reusable. At UNIQA DENTAL you can buy transfers made of titanium alloy with vanadium and aluminum Grade 23. Titanium transfers are much stronger and more resistant to wear than stainless steel. And the price of transfers from UNIQA DENTAL remains reasonable considering that they will be used for a very long time.

The impression taking procedure is unpleasant for the patient and requires a lot of time and effort from the dentist. Therefore, digital CAD/CAM technologies are increasingly being used, where the jaw model is obtained as a 3D file. Dental implants are scanned with markers and the oral cavity is scanned with an intraoral scanner. The procedure takes a few minutes and the patient can be released. Next, there are two ways to proceed:

- If necessary, a 3D model of the jaw is printed, in which you can also insert implant analogs or implant and abutment analogs in a single piece. And work with the printed model the same way as with the model cast.

- Create a digital model of a crown or bridge structure on the basis of 3D model of a jaw and produce it on a CNC machine. The restoration in the form of a crown or bridge can be either permanent or temporary. Temporary restorations are made of strong polymers and are most commonly used if an immediate restoration of the aesthetic zone has been made. Polymeric restorations are much lighter than permanent restorations and can relieve the pressure on the implants. This is important for successful osseointegration. The temporary crown or bridge can also be partially relieved from the bite to relieve the pressure before the full integration of the dental implants.

Implant analogs

The abutment analog is fixed with copings that remain in the impression, or are removed from the implants and placed in the impression if the impression procedure was done with the tray closed.

The upper part of the implant analogue is clearly in the same place as the real implant, the interface of the implant analogue coincides with the interface of the implant in the patient’s jaw.

UNIQA DENTAL produces abutment analogues for the most common abutment interfaces, namely: standard hex, 22 and 24° cone.

Both direct and angled analogues of implants are available for ordering (the latter are needed for complex cases). Abutment analogs from UNIQA DENTAL are also made of the strongest titanium alloy to ensure maximum reliability and long service life. Keep this in mind when choosing, because many manufacturers offer analogues of abutments and non-ferrous metals. But even tightening a laboratory screw can deform the threads of such a product, and it will be problematic to reuse it.

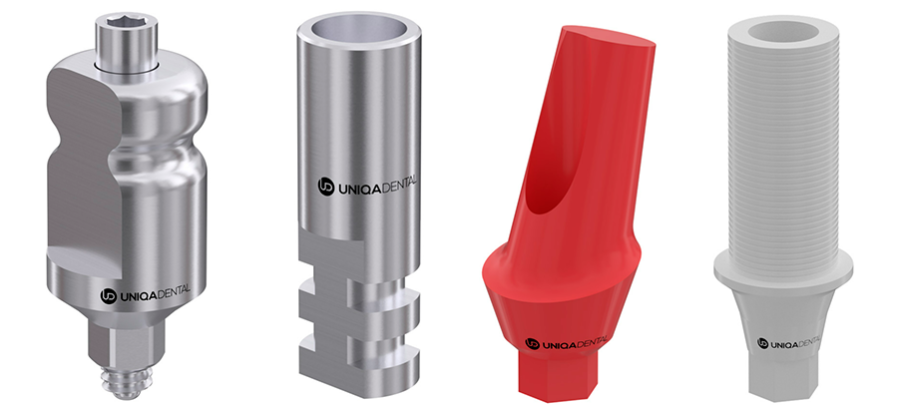

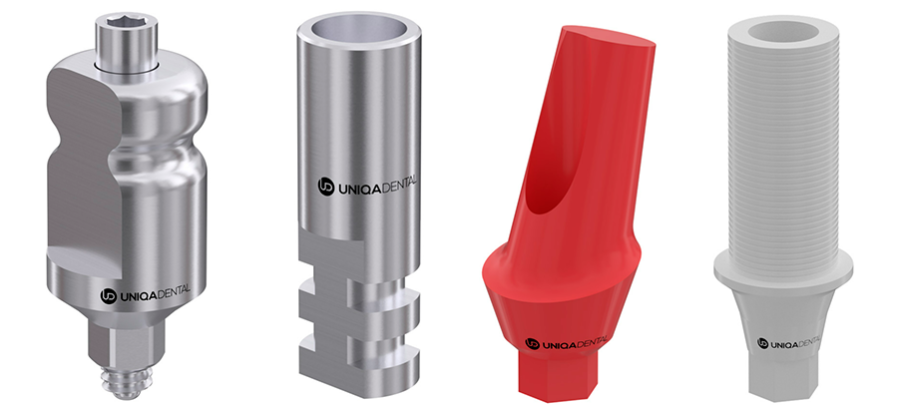

Cast abutments (polymer castable)

Another element for the fabrication of crowns that can be purchased on this site are polymer abutment models. They are needed to form a ceramic crown around them. During the sintering process of the ceramic mass, the plastic is burned out and a cavity remains in the ceramic crown that is completely identical to the clinical abutment placed in the patient’s mouth.

Burnable abutments are made of a special plastic that leaves no ash or resin on the inside surface of the cavity. During combustion, the entire material completely transforms into a gaseous state.

The crown obtained with a cast abutment is designed for cemented fixation. It is a reliable and well-proven technology. Although, in recent years, it has been increasingly inferior to screw-retained platforms such as T-base for single restorations and Multi-Unit for multiple restorations, including full dentures. The Multi-Unit platform can also be ordered with burnout sleeves for crown fabrication. You can find them in the corresponding section.

Why cooperate with UNIQA DENTAL is beneficial

Our company is not the only manufacturer of elements for implants and dental restorations. But UNIQA DENTAL has a number of advantages:

- research and development is carried out continuously at UNIQA DENTAL. Even well-tested methods and techniques are constantly changing and improving. As a result there are new methods of making the surface roughness of dental implants and the smallest tolerances in the size of parts.

- UNIQA DENTAL team consists of highly qualified specialists who have mastered allied specialties. Dentists have gained fundamental knowledge in chemistry, materials science and functioning of modern engineering equipment. Also the engineering staff understands what is important for patients and dentists.

- UNIQA DENTAL manufacturing facilities are not only state-of-the-art machines, but also a highly developed workflow, which minimizes time delays during the transition from one processing stage to the next.

- Free shipping from one unit regardless of price.

- Warehouse in the U.S. so you can get your order within 1-2 days of placing your order.

You can also order test samples by leaving an order by any convenient way.