When to use angled multi-unit abutments

Unfortunately, there are quite a few clinical cases where it is not possible to place the implant in the anatomically correct position relative to the occlusal plane. This may be due to:

- Placing implants in the upper jaw. Often the bone thickness there is insufficient and so as not to make a through hole in the maxillary sinus the implants must be angled so that they are in the bone thickness, see the illustration below. It is possible to compensate for the deviation with an angled MUA.

Dental implant placement at an angle to bypass the internal cavities of the skull

- Immediate implantation protocol. After a tooth extraction there is a large enough cavity that was occupied by the root of the tooth, but the root implant simply won’t hold with enough stability. Usually, in such cases, the implant is long enough so that its apical part sits in the bone and provides acceptable primary stability. When this is not possible, however, it makes sense to use an implant that is offset from the root of the extracted tooth. This will allow the implant to be anchored in sufficiently dense bone.

- Damage and insufficient bone density in the area of the restoration. This problem is most often encountered in the area of molars. If several years have passed since the loss of a tooth, the alveolar ridge shrinks, and the implants need to be placed at an angle to securely hold them in place. Especially if we are talking about a group restoration for 3-4 teeth, which will be supported by two implants.

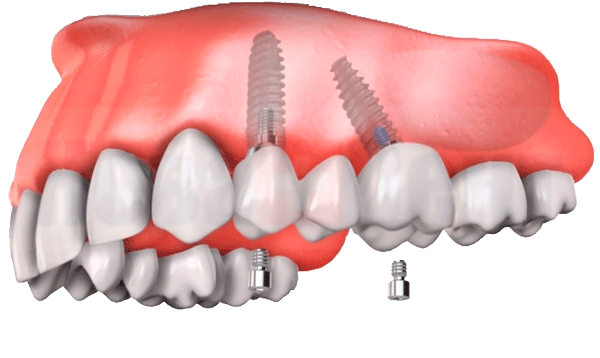

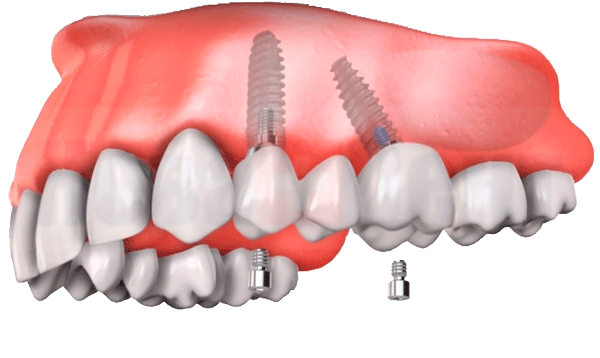

- The placement of a full denture for absolute adentia according to the protocol “All on 4®” or “All on 6®”. At least four implants (two on the upper jaw and two on the lower jaw) are placed with a deviation to distribute the load evenly on the jaw. To compensate for the deflection, you have to buy angled MUA, see the picture below.

Complete dental restoration with screw fixation and angled abutments

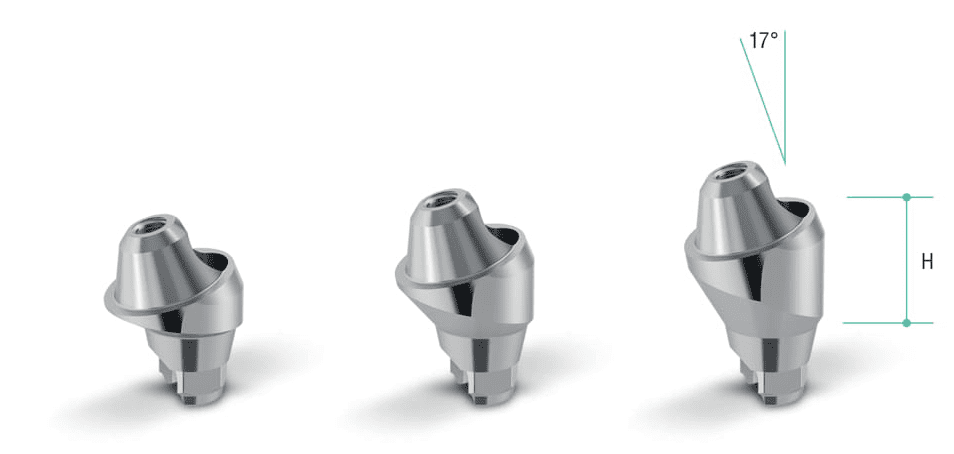

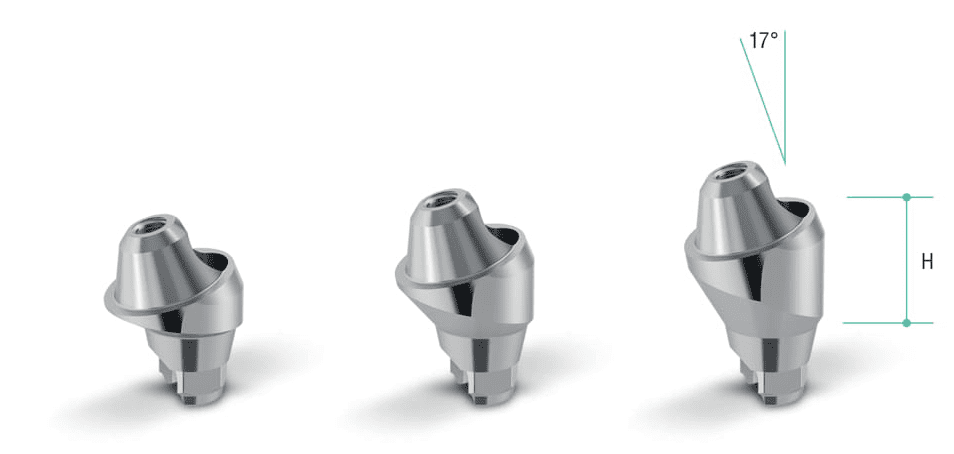

In terms of dimensions, the Uniqa Dental website offers several height options for angled multi-unit abutments ranging from 1 to 3 mm. Since the part is asymmetrical, the question arises on which side the height and angle are determined. The answer to this question is in the illustration below.

How the compensation angle and height of angled multi-unit abutments are determined

Advantages of screw-retained multi-unit abutments

The screw fixation of the denture to the abutments was developed to avoid cementing operations in the patient’s mouth and to make it easy to remove the denture if required. Also, prosthetics on multi-unit abutments allows complex restorations to be made with a very precise fit, without internal overstressing, which increases the longevity of the prosthesis, and reduces the time for all procedures related to the placement of the prosthesis and also reduces the risk of complications.

Here’s a list of the advantages of a screw-locked platform over a cement-locked one:

- Easier to implement for a specialist. Cement fixation of a complex prosthesis is a time-consuming process that requires experience and skill from the dentist. Screw-retained dentures are easier, many of the complex procedures take place outside the patient’s mouth, and using CAD/CAM systems. On straight and angled multi-unit abutments, it is easier to achieve a good passive fit without internal overstressing, which reduces the risk of abutment screw loosening and breakage.

- Cement residue contact with the soft tissues of the gum is avoided because all cement surgeries are performed outside the patient’s oral cavity. It is practically impossible to remove cement residues qualitatively if the crown is fixed in the oral cavity. Small particles of adhesive remain in the line between the crown and abutment. Direct contact of the cement with soft tissues leads to chronic inflammation of the gum, which can even lead to the loss of the implant.

- The abutment is fixed once and for all with considerable torque. If the restoration needs to be removed for repair or replacement of the temporary restoration with a permanent one, the screw shafts are simply opened and the denture is unscrewed and all further manipulation again takes place outside the patient’s mouth. The angled mullion-unit abutment is immobile and does not experience overloading. After all the manipulations are completed, the denture is screwed back in and the screw shafts are filled again. In the case of cemented fixation, the denture would have to be knocked down and then a new bridge or splinted structure would have to be made. This requires time and money. Therefore, the higher price of angled multi-unit abutments pays off in the long run for both dentist and patient.

- Better distribution of the load from the dentures on the implant, especially laterally. With screw fixation on multi-unit abutments, the load is distributed over the greater depth of the implant, while with cemented implants there is significant overload at the top of the implant. This is especially true for thin implants with a diameter ≤ 4 mm, there is a rather thin wall of the implant body of 0.4-0.5 mm in the upper part. The problem area is shown in the illustration below.

Implant with angled multi-unit abutment in section

The MUA abutment transfers the load through the screw to the considerable depth of the implant, thereby reducing overload in the problem areas.

- There is little or no micro-mobility at the implant/abutment level. There is always a gap between the implant and abutment and the smaller the gap, the better the antimicrobial barrier. Achieving minimal clearance and immobility with screw fixation is much easier. This means that the “pum-pum effect” is minimized, when chewing, the alternating forces on the abutment lead to the “pumping” of saliva and bacteria into the internal structures of the soft tissues. As you know, it is the gingival cuff that separates the non-sterile space of the oral cavity from the sterile space of bone and soft tissue. The entry of microflora into the sterile environment leads to chronic inflammation and even peri-implantitis. This is a very serious problem, which threatens not only the loss of the implant, but can also cause significant harm to the patient’s health.

- Good results and a passive fit can be obtained even in very difficult cases where there is a significant bone deficit and the implants have to be placed at significant angles relative to the dentition line. With straight and angled multi-unit abutments, even very complex restorations can be easily achieved with a passive fit.

Screw-retained lower denture restoration

- Angled multi-unit abutments can be used to achieve a good fit at very low crown heights. There are cases where the crown has to be 4-5 times the height of the implant. With cemented fixation, the abutment would be sunk no more than 3 millimeters into the crown. Which is very little and in six months the cement would have crumbled. In the case of screw fixation, even a low crown height and a short sleeve give a good and long-lasting result.

Materials used in angled multi-unit abutments

Uniqa Dental uses titanium-vanadium-aluminum alloy Grade 23 for implants and all types of abutments. It is one of the most promising materials due to its high strength, but the key advantage is its high elasticity (Young’s modulus). Only a few types of medical titanium are used for dental implants:

- Grade 4 is technically pure titanium, with sufficient strength and excellent osseointegration performance, but is quite brittle;

- Grade 5 is a titanium-vanadium-aluminum alloy is much stronger than the previous version, which is good for making thin and thin-walled parts, but is also quite brittle;

- Grade 23 is an alloy of titanium with vanadium and aluminum, but with a reduced content of impurities, particularly oxygen, with a strength almost equal to the previous one. However, it is much more ductile and tolerates elastic deformation well without fracture.

This is why Grade 23 was chosen as the material used in Uniqa Dental angled multi-unit abutments.

Why angled abutments are only used for group restorations

Straight and angled multi-unit abutments cannot be used for single-tooth restorations because of the interface features. The connection to the denture is through a tapered sleeve that is glued into the restoration. The angled abutment/sleeve interface has no antirotation elements, which means that the risk of rotation of the crown relative to the abutment is too great.

For single restorations, there are screw-retained systems such as t-base abutments.

Angled multi-unit abutments compatible with other brands of implants

Uniqa Dental’s angled multi-unit abutments are available with a standard inner hex and are compatible with implants from the other manufacturers listed below that support this standard:

Why it is profitable to buy angled multi-unit abutments through Uniqa Dental website

There are many manufacturers of dental implants, but you should assess whether all of them can offer the same quality and service as Uniqa Dental. If the scales tip in our favour and you decide to buy angled multi-unit abutments and other components from Uniqa Dental, you will get:

- Perfect quality because we invest in technology, not marketing with beautiful brochures and loud promises. It’s not just about the future-oriented Grade 23 titanium alloy, but also about the highest precision manufacturing. Maximum tolerances of ±0,02 mm for all parts. This reduces the risk of screw loosening and creates an antimicrobial barrier due to the tight connection in the implant/abutment line.

- Free delivery of any components anywhere in the world. Within the U.S., delivery is within 1-2 days if you choose the USPS postal service.

- Easy and hassle-free returns

- Free electronic library of angular multi-unit abutments and sleeves for CAD/CAM modeling and fabrication of dental restorations.

You can also order test kits from us for $0.99 or $9.99 (the latter comes with a full implant). To get a test kit, leave a request and we’ll send you an evaluation kit.