Straight multi-unit abutments are the basic elements in screw-retained denture restorations. It is the straight MUA that holds the bridge and assumes the vertical and lateral loads during chewing. The straight screw-retained abutment must be fabricated with the highest precision. It must sit firmly in the implant cavity without gaps and micro-movements. An accurate and tight connection provides an antimicrobial barrier and prevents bodily fluids from entering the internal cavities of the implant. The seating stability of the abutment is extremely important. Unlike the root of a living tooth, an implant does not have a full-fledged ligament apparatus, and the patient does not receive good feedback on the density of the food clump that he or she is chewing. As a consequence, excessive forces may be applied, and if the abutment has gaps and internal overstresses, sooner or later it will unravel, or the screw that holds the abutment will break.

When straight multi-unit abutments are used

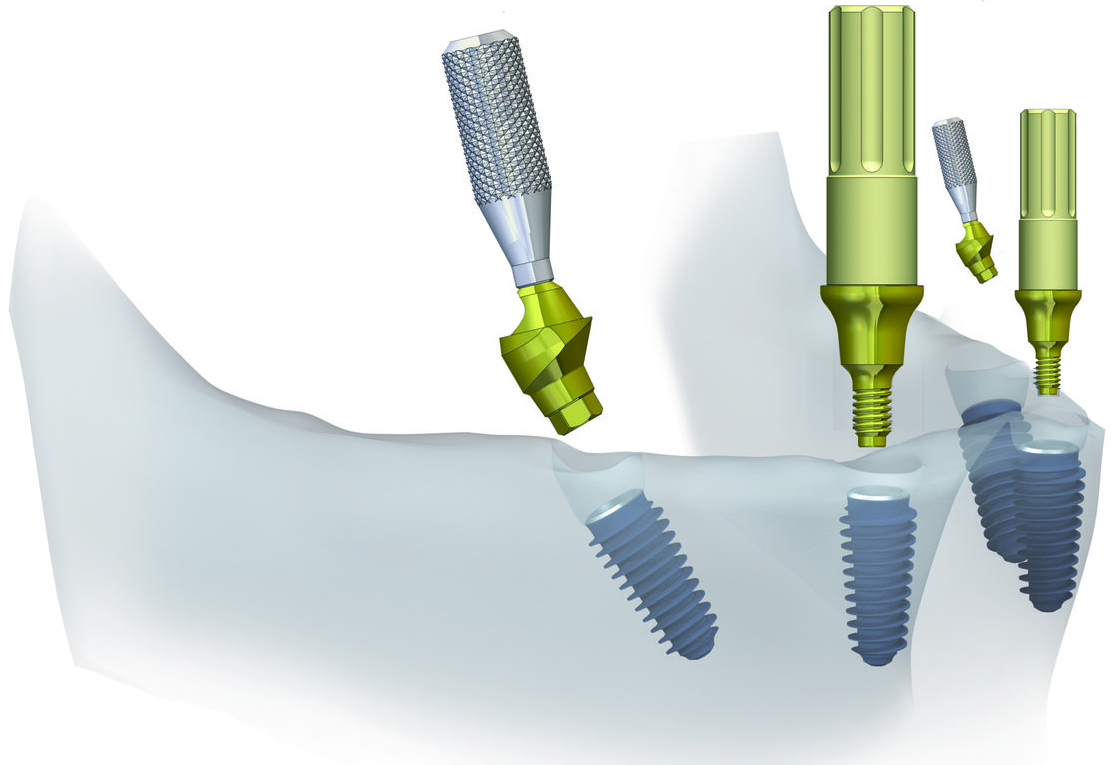

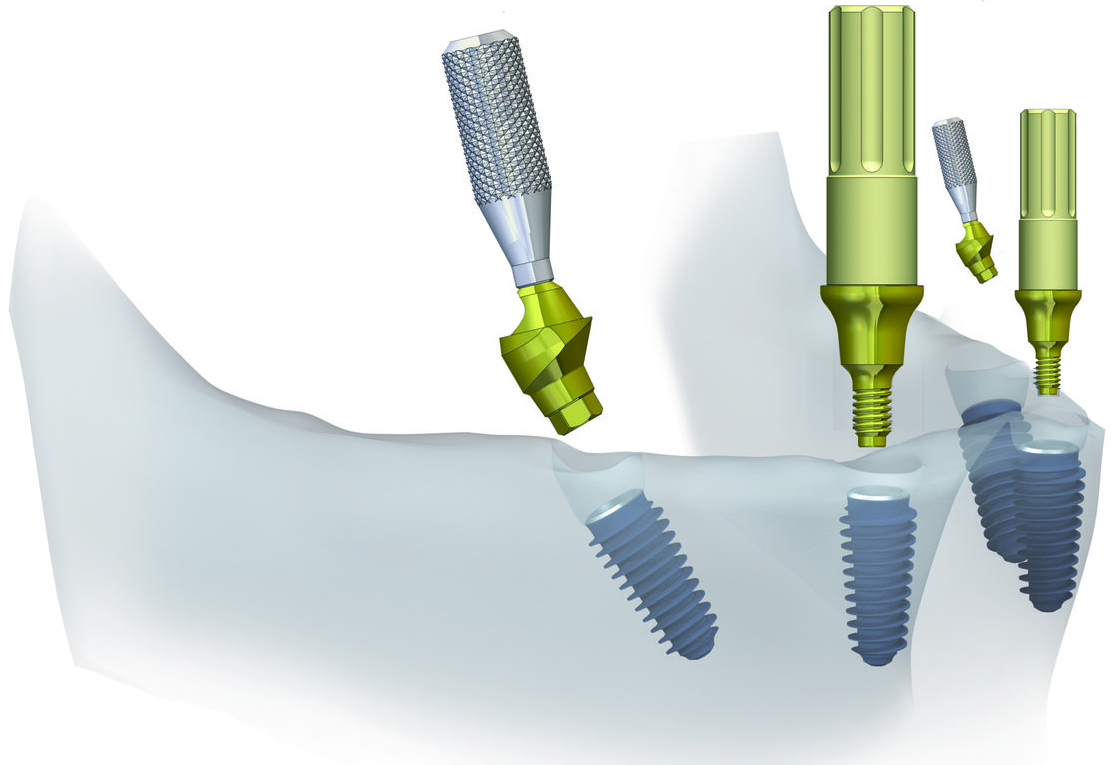

The straight multi-unit abutment system is used in most cases and is preferred if there are no indications for angled abutments. Straight MUAs can only be used for group restorations of two teeth or more. Straight MUAs are also used for the treatment of complete edentulism in “All-on-four” or “All-on-six” systems. Only in these cases at least two angled abutments must be used in conjunction with straight multi-unit abutments, see illustration below.

Lower jaw implantation model all on 4 – angled and straight multi-unit abutment placement stage

The design of a straight multi-unit abutment depends on:

- Connecting interface. Straight multi-unit abutments for tapered connection (Morse taper) and 1.5 mm inner hex can be purchased through our website. Design options for straight multi-unit abutments can be seen in the illustration below.

Straight MUAs with different interfaces – from left to right: conical interface type PR; conical interface type MP; internal hexagonal connection

- The patient’s soft tissue heights around the implant. Each straight multi-unit design has at least four different heights. Here is what two straight multi-unit abutments look like for different gingival heights.

Straight MUA with tapered MP taper connection for 1 mm (left) and 4 mm (right) gingiva

Let’s summarize:

- Straight multi-unit abutments for complete dental restorations are used extensively, but most often in combination with angled abutments.

- The straight multi-unit abutment system can be used for the treatment of partial adentia, when two to four teeth are missing.

- The straight MUA is not suitable for single restorations because the head of the abutment and the sleeve to which it fits have no antirotation elements. This means it can rotate under load. Other screw-retained abutments are used for single restorations.

Advantages of straight multi-unit abutments over cemented fixation

Screw-retained dentures on the multi-unit system are more advanced than cement-retained dentures. These are the main advantages of straight multi-unit abutments:

- It is easier for the dentist to work with screw fixation than with cemented fixation. Most of the complex and time-consuming manipulations take place outside the patient’s mouth. If the denture has been fabricated in its entirety using CAD/CAM systems, it requires no fitting and is immediately placed on multi-unit abutments without internal overstretching.

- The patient’s soft tissues do not come into contact with the cement residues. In the case of screw fixation, cement is only used to glue the sleeves into the finished denture. The sleeves are then fixed on the tapered head of the straight MUA. These dental cement operations take place outside the patient’s oral cavity. In the case of cement-retained crowns on the abutment, it is almost impossible to completely remove the residual cement. Small particles of adhesive remain in the line between the crown and abutment. Contact of the cement with the soft tissues leads to chronic inflammation of the gingiva, which can even lead to the loss of the implant.

- Less bone resorption around the implant and better gingival cuff quality around the implant. The straight multi-unit abutment is fixed once and for all with considerable torque. To remove the temporary and place the permanent restoration, simply open the screw shafts, unscrew the screws, remove the old denture and place the new one in its place. The straight multi-unit abutment is immobile and is not overloaded. In the case of the cemented technique, the abutment is removed and repositioned several times for adjustments and other manipulations. Each time the gingival cuff is traumatized and the collagen fiber complex is lowered, thereby dissolving part of the bone tissue to make room for connective tissue adhesion.

- The load distribution from the denture to the implant is better, especially the lateral load. The multi-unit abutment transfers the load to a, where the walls are thinnest. If implants ≤ 4 mm in diameter are used, the implant wall thickness is only 0.4-0.5 mm.

- Minimum micro-mobility at the implant/abutment level. There is always a gap between implant and abutment and the smaller the gap, the better the antimicrobial barrier. Angled and straight multi-unit abutments allow for much better performance. This is due to several factors. Importantly, a multi-unit abutment is fixed once, and if there aren’t multiple removals and placements, the parts will hold tighter. The second important factor is the precision of the interface and here UNIQA Dental has something to be proud of. The maximum precision tolerance of the parts is ±0.02 mm. A high-quality and tight connection is very important, firstly, it reduces the risk of screw unscrewing, and secondly, it minimizes the so-called “pamp effect”, when during chewing the alternating load on the abutment leads to “pumping” of saliva and bacteria into the internal structures of the implant and deep into the gingival cuff tissue.

- Prosthetics on straight multi-unit abutments allow for an excellent passive fit even in very difficult cases where there is a significant bone deficit and the implants have to be placed at significant angles relative to the dentition line. This is especially so when the prosthesis is fabricated with high precision using CAD/CAM technology.

- The placement of a straight multi-unit abutment allows for a high quality retention with a very low crown height. There are cases in which the crown has to be 4-5 times the height of the implant. With cemented fixation, the abutment would be sunk no more than 3 millimeters into the crown. Which is very little and in six months the cement would have crumbled. In the case of screw fixation, even a low crown height and a short sleeve give a good and long-lasting result.

What materials are used to make straight multi-unit abutments?

Uniqa Dental has selected titanium-vanadium-aluminum alloy Grade 23 as the material of choice for straight multi-unit abutments, implants and all other prosthetic components. Not all manufacturers use this alloy, but it is one of the most promising materials. Its strength is higher than that of Grade 4 pure medical grade titanium, but its key advantage is its ability to withstand elastic deformations (Young’s modulus). That means that a Grade 23 part will bend or stretch under load and return to its original state. A Grade 4 or even Grade 5 part will break under the same load.

Let’s take a closer look at the materials for implants and their accessories:

- Grade 4 is technically pure titanium, with sufficient strength and excellent osseointegration performance, but quite brittle;

- Grade 5 is a titanium-vanadium-aluminum alloy much stronger than Grade 4, which is good for making thin and thin-walled parts, but it also quite brittle;

- Grade 23 is an alloy of titanium with vanadium and aluminum, but with a reduced content of impurities, particularly oxygen, with a strength almost equal to Grade 5, but it is much more ductile and tolerates elastic deformation well without fracture.

Compatibility of straight multi-unit abutments with interfaces of other manufacturers

Straight multi-unit abutments from Uniqa Dental are compatible not only with branded implants but also with most third-party implants. Check the compatibility table for Uniqa Dental straight MUA’s with other brands.

| Type of interface |

Brands with 100% compatibility |

| Cone PR |

Hiossen ET III RP®, Osstem® ET III RP® |

| Cone MP |

Hiossen ET III MP®, Osstem ET III MP® |

| Internal Hex |

Zimmer®, MIS®, BioHorizont®, Impan Direct®, XGate Dental®, AlphaBio®, Adin®, AB®, Cortex®, JD Evolution® |

Why it is profitable to buy Straight multi-unit abutments from Uniqa Dental

Before deciding which platform for prosthetics to choose, familiarize yourself with the benefits that Uniqa Dental clients receive:

- Perfect quality because we invest in technology, not marketing with beautiful brochures and loud promises. It’s not just about the future-oriented Grade 23 titanium alloy, but also about the highest precision manufacturing. Maximum tolerances of ±0,02 mm, for all parts. This reduces the risk of screw loosening and creates an antimicrobial barrier due to the tight connection in the implant/abutment line.

- Free delivery of any components anywhere in the world. Within the U.S., delivery is within 1-2 days if you choose USPS postal service.

- Easy and hassle-free returns.

- Free electronic library of angled multi-unit abutments and sleeves for CAD/CAM modeling and fabrication of dental restorations.

You can also order quality test kits with the basic components. There is a trial kit option without the implant for $0.99 or with the implant for $9.99. To get a test kit please leave a request and we will send you a trial kit.