A new high-speed bioprinter from Melbourne – how it works and who it’s for

Biomedical researchers from the University of Melbourne have unveiled a state-of-the-art 3D bioprinting system that promises to revolutionize the way researchers replicate human tissue. Unlike traditional bioprinters, which are limited by slow and imprecise processes, this revolutionary technology uses innovative acoustic wave manipulation to position cells with unprecedented precision. This achievement holds tremendous promise for fields such as cancer research, drug testing and tissue engineering. We are not yet talking about printing human organs or tissues suitable for implantation to replace diseased or damaged ones, so far it is only tissue models on which scientists are working out treatment methods and new drugs. But obviously the next step is the creation of living tissues outside the body, which can then be placed in the human body and take root. For specialists in dentistry and maxillofacial surgery, the development of technologies in this direction is extremely interesting.

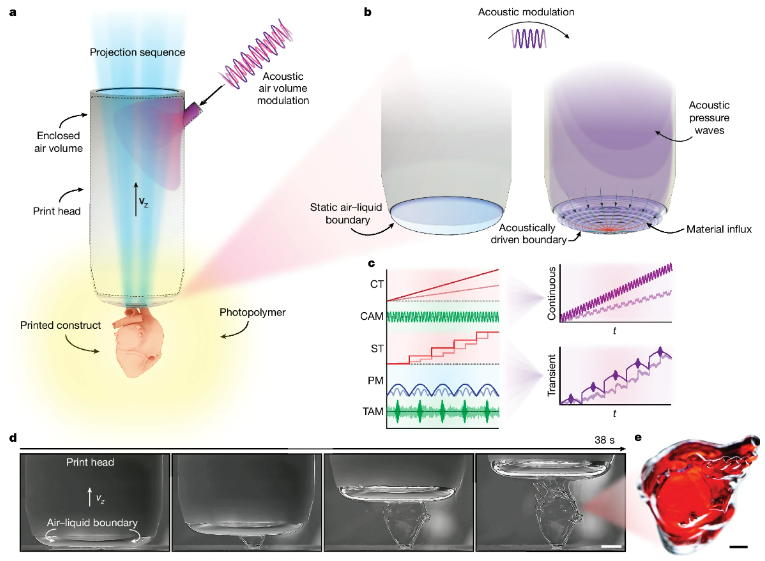

A, an air–liquid boundary forms at the base of a partially submerged print head. The boundary acts as a print interface in which patterned projections are used to locally solidify the photopolymer. B, acoustic manipulation of the internal air volume in the print head promotes enhanced material influx through capillary-driven waves. C, in continuous mode (top right), the global location of the air–liquid interface(s) depends on continuous translation (ct) of the print head and constant acoustic modulation (cam). In transient mode (bottom right), the location of the interface depends on stepped translation (st), internal pressure modulation (pm) and transient acoustic modulation (tam). D, time-lapse photographs of the printing process for a heart geometry, demonstrating rapid fabrication of centimetre-scale constructs in less than 40 s. E, printed heart geometry as shown in d, dyed red to improve visualization. Scale bars, 5 mm (d), 2 mm (e).

Key Innovations in Bioprinting

Acoustic Wave Technology for Precision Cell Placement

One of the most significant challenges in traditional 3D bioprinting has been achieving precise cell positioning. Most existing systems rely on natural cell alignment, leading to inaccurate structures. The University of Melbourne’s approach utilizes acoustic waves generated by vibrating bubbles to guide cells precisely within the printed matrix. This method ensures that cells start developing into complex tissue structures more effectively, mirroring how organs function in the human body.

“Just as a car requires its components to be arranged perfectly for proper function, our tissues need cells to be organized precisely,” explains Associate Professor David Collins, head of the research team.

Speed and Efficiency: 350 Times Faster Printing

Speed is critical for maintaining cell viability in 3D printed structures. Traditional methods can take hours to complete, endangering cell survival and requiring careful, often damaging, transfers to laboratory plates. The new bioprinting system eliminates these inefficiencies by printing cellular structures in mere seconds. It achieves a speed that is 350 times faster than conventional techniques, significantly boosting cell viability and maintaining the integrity of delicate tissues by printing directly into standard lab plates without additional handling.

Diagram of Acoustic Wave Cell Positioning

The use of acoustic modulation creates a dynamic print interface where cells are actively guided into place, rather than passively settling. This approach ensures greater fidelity and structural integrity, key to forming lifelike tissues.

Transformative Applications in Biomedical Research

Accelerating Drug Discovery and Cancer Research

The rapid and precise bioprinting capabilities have transformative implications for drug discovery. Researchers can now fabricate tissues that replicate the cellular environment of human organs with high accuracy. This advancement enables more effective pharmaceutical testing, reducing reliance on animal models and expediting the path to new medical treatments. The team has already collaborated with institutions like Harvard Medical School and the Sloan Kettering Cancer Centre, receiving positive feedback on the technology’s potential to bridge gaps between laboratory research and clinical applications.

Broader Impact in Tissue Engineering and Regenerative Medicine

Beyond cancer research, the bioprinter’s adaptability to different bioinks and materials enhances its utility for engineering diverse tissue types, from skin to cartilage. The system’s acoustic manipulation also minimizes cell sedimentation and ensures even distribution, crucial for creating complex scaffolds and organ models. This adaptability makes it a powerful tool for regenerative medicine, where creating viable tissues quickly and accurately is critical.

Conclusion: A Leap Forward in 3D Bioprinting

The University of Melbourne’s 3D bioprinting innovation stands out for its speed, precision, and cell viability, marking a substantial leap forward in biomedical research technology. By tackling long-standing challenges in cell positioning and reducing production times, the technology paves the way for a new era in personalized medicine and advanced tissue engineering. With continued collaboration and development, this bioprinter is set to redefine the standards of medical research and therapeutic development.

Sources

- ScienceDaily – Revolutionary high-speed 3D bioprinter hailed a game changer for drug discovery – November 1, 2024

- Nature – Dynamic interface printing October 30, 2024