How Dental Implant Drills Can Reduce the Risk of Implant Failure

Contents

In this article, we will discuss drills that can improve implant success rates. Specifically, we are referring to two-step graphite-based coated drills, which are available for purchase on the Uniqa Dental website. However, our focus is not on commercial terms but on the product’s characteristics.

Colleagues understand the challenges of working with certain types of bone and the high risk of complications in patients with diabetes or early-stage osteoporosis. Coated two-step drills reduce these risks and can assist even those who were previously ineligible for treatment. Let’s explore how the shape, sharpening, and coating of the drill affect bone tissue condition during implant site preparation.

Design features of two-step coated drills

Let’s look at the design of two-step coated drills using the illustration below. The first thing we notice is the two diameters, D1 and D2. The second step of the drill has a larger diameter (D2) than the first (D1), allowing it to pass through bone tissue with less effort. This design enables the drill to move more accurately and stably. This shape is suitable for installing both straight and conical implants, providing stable results even in bones with low density (D3, D4). The transition to the second diameter occurs immediately after the tip, where a step of larger diameter is clearly visible.

Two-step coated drills are truly universal; you can see the notches on the working part, the first of which is located 6 mm from the tip. This means the surgeon clearly sees the depth of the drill.

With six diameter options and a length of 16 mm, you can install almost any implant from any manufacturer.

Color-coded two-step coated drills

During the operation, there is no time to check the engraving for the diameter, so the drills are clearly color-coded. Please refer to the table below.

Drill diameter variety

| Drill appearance | Diameter D1/D2 | Color |

|---|---|---|

|

2.0/2.0 | White |

|

2.0/2.8 | Red |

|

2.8/3.2 | Blue |

|

3.2/3.7 | Green |

|

3.6/4.2 | Black |

|

4.2/4.6 | Yellow |

Coated implant drills

The drill tip, as well as the belt in the middle part, have a multi-layer coating called DNT2, which is clearly visible due to its dark gray color. The advantages of the DNT2 multi-layer coating include:

- Heat reduction drilling due to reduced friction: Graphite lubricants and coatings have long been known in mechanical engineering and are now being used in medicine. Preventing the bone from overheating is crucial because implants often fail due to burns to the bone tissue. If the drill temperature exceeds 50°C, the bone tissue is damaged, leading to necrosis rather than osseointegration after implant placement. This necessitates the removal of the implant, along with a significant amount of bone tissue. The cavity must then be filled with a bone graft, followed by a waiting period for healing and complete restoration of bone tissue before the implant can be replaced. This process is very expensive and time-consuming, and it may not be covered by the patient if the problem is determined to be the surgeon’s fault. Therefore, it is important for dentists to continually improve their skills and select precision implantology tools.

- Increased cutting edge life and overall drill longevity: Less friction results in less wear and dullness. Given the quality of the tool steel used in coated two-step drills, it is not surprising that they can be used 50 times or more without loss of performance.

- Chemically and biologically compatible coating properties: Biocompatible DNT2 coating is extremely important because the drill invades a sterile environment and comes into direct contact with bone tissue. Microparticles of the material will inevitably remain on the bone tissue, and they should not provoke inflammation or cause any harm to the body.

-

Sale!Original price was: $3,900.$2,535Current price is: $2,535.

Benefits of two-step coated drills for dental implant procedures

We have already partially described the advantages of new drills for implantation, but now we need to summarize:

- Increased speed of implant site preparation: A coated drill with active cooling penetrates bone tissue faster. Every surgical intervention carries risks, and the sooner the operation is completed, the lower the risk of complications.

- Osseointegration enhancement: Two-step coated drills, thanks to their two steps with increasing radius, precisely cut without crushing trabeculae or compacting bone tissue at the cutting boundary. This allows biological fluids and living cells to come into unhindered contact with the implant surface during the healing process. Consequently, osseointegration begins earlier, as the body does not need to resorb damaged tissue and restore the structure first, which would otherwise slow down osseointegration.

- High precision of implant site preparation: The accuracy of implant placement depends on the surgical template and the surgeon’s experience. However, when the drill moves smoothly and is fully controlled by the surgeon, the risk of error is minimal. The site is smooth and matches the implant diameter precisely, ensuring good primary stability, which is critically important, especially for immediate implantation after tooth extraction.

- Bone preservation drilling: We have already mentioned that sometimes drills crush trabeculae and compact bone tissue on the site walls instead of cutting cleanly. The developers of two-step coated drills have designed them to ensure a clean bone cut. Additionally, reducing the temperature helps preserve bone tissue.

Comparison with conventional implant drills

Some complications during the installation of dental implants can arise even at the stage of bone tissue preparation. These complications directly depend on the tool used.

| Risks when installing an implant | How the risk of complications may depend on the surgical instrument | Conventional twist drills without coating | Two-step coated drills |

|---|---|---|---|

| Inflammation and rejection or fibrointegration of the implant. | Inflammation can occur after overheating of bone tissue. Necrosis does not always occur, but sometimes, instead of integrating with bone tissue, a layer of connective tissue forms between the implant and the bone. | Active irrigation and reduced rotation speed reduce the risk of overheating, but the risk remains quite high. | Active irrigation + DNT2 coating reduce the risk of overheating. There is no need to reduce the rotation speed, which is beneficial for the quality of bone tissue cutting. |

| Nerve damage or drill displacement into the maxillary sinus. | The reason may be poor planning of the operation, insufficient experience of the surgeon, or the quality of the drill. | Such drills typically have one or two notches, approximately 10 mm from the tip, making it difficult to estimate the exact depth of immersion, increasing the risk of nerve damage or sinus perforation. | Notches at five levels of depth provide maximum control of drill immersion, minimizing the risk of hitting a nerve or entering a sinus. |

| Poor stability of the implant due to low bone density and slow regeneration due to the patient’s chronic diseases. | It is easy to damage the trabecular structure and crush bone tissue. Initially, crushing and compaction of bone tissue can give the illusion of good primary stability, but problems with osseointegration are inevitable. | Not always the optimal sharpening angle and straight drill profile, combined with low drilling speed, leads to bone injury. | The stepped shape with a smaller diameter tip allows for cutting bone without crushing trabeculae and compacting bone tissue, even in low-density bone. The chance of successful osseointegration is quite high, although it is never 100%. |

Recommendations for using two-step coated drills

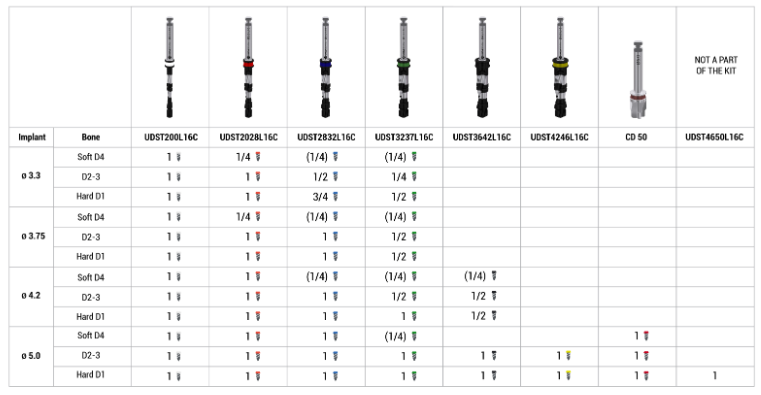

The use of new drills for implantation does not require deviations from the standard drilling protocol. However, there are recommendations on how to choose the sequence of drill diameters. The table below suggests the use of two-step coated drills based on bone type and implant diameter, including a cortical bone drill bit. Please note that the recommendations for a drilling depth of 1/2 or 1/4 of the site depth are somewhat arbitrary and depend on the length of the implant. Minor deviations of 1 mm in any direction will not affect the final stability of the implant.

Selection table for two-step coated drills for placing implants with a diameter of 3. 3 to 5. 0 mm, in bones of different densities, including a cortical bone drill bit

Conclusion

We won’t reiterate the cutting efficiency of the new drills, as everything has already been covered above. If you have any technical questions, our consultants are available to answer them. However, potential buyers might have questions about the ordering procedure, such as delivery times and the return process if something doesn’t fit. Let’s address these in order:

- Two-step coated drills are in stock in significant quantities, so there is no need to wait for production. You can simply order and receive either a single unit or a set of six drills.

- Delivery within the United States is provided by Uniqa Dental. The delivery speed depends on both the delivery service you choose and warehouse availability in the United States. If the product is in stock in New Jersey, you will receive your order in 1-2 days. There is also an option for paid overnight delivery, where the order will be delivered the next morning. If the shipment comes from Israel, the delivery time is 5-8 days.

- If the product is not suitable for any reason, it can be returned, provided the packaging integrity is not compromised. Read our complete return policy for detailed information about the process.

We hope our readers are interested in advanced implantology techniques and are eager to introduce advanced technologies and tools into their practice. Stay in touch, and until the next publication.