Individual and standard abutments – features and benefits

Contents

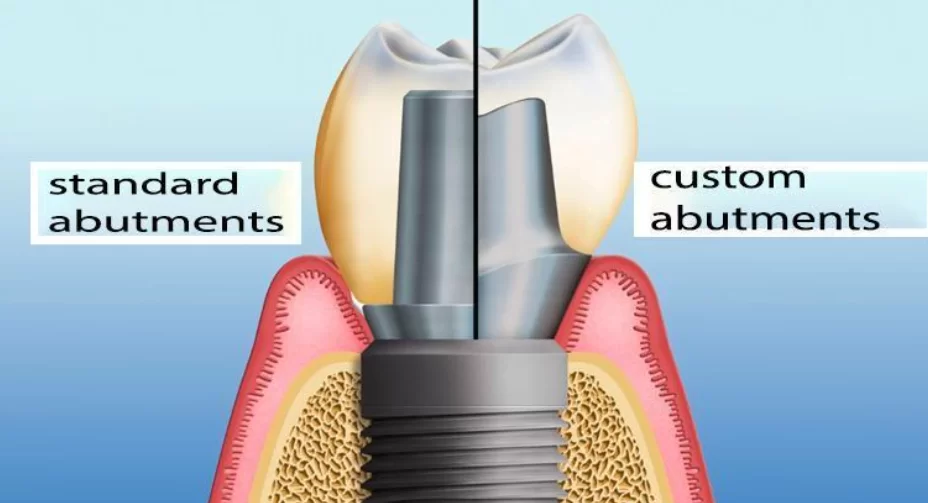

In this article, we will analyze the advantages and disadvantages of using standard type abutments (factory-made) and individual molded abutments made by a dental technician. Restoration on individual abutments is more accurate, all the nuances with the deviation of the implant relative to the existing teeth are taken into account, and the pairing of the gums with the crown is performed with perfect accuracy. Even standard solutions make it possible to obtain an equally high-quality restoration, both from a functional and aesthetic point of view. Both technologies continue to exist, and the purpose of this review is to find out how much better an individual abutment does its job and whether it is worth spending additional effort, time and money on its creation.

Clinical cases in which it is recommended to install individual abutments

Orthodontists rarely encounter perfectly placed implants, so there are only two clinical cases when it is recommended to use individual solutions:

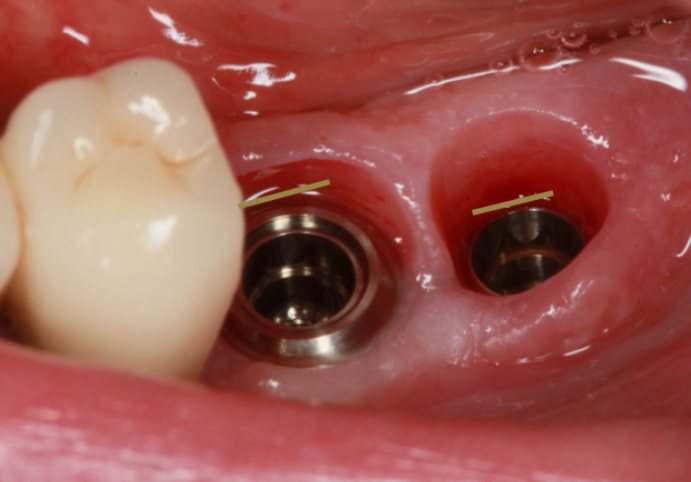

- Deviation of implants relative to the occlusal plane horizontally. This means that the implants are installed below or above relative to each other or the existing dentition. The picture below shows an example of two adjacent implants forming steps relative to each other.

- The implants are installed with a vertical deviation relative to the occlusal plane, see the picture below.

There are prefabricated angled abutments that can compensate for significant implant deflection, but they have a fairly large step – 17, 25 or 30 °, which means they have to sacrifice something. Grind the abutment too far or form a crown with a critically thin wall thickness on either side. An individual abutment facilitates compensation for deviation with high precision.

Properties and varieties of standard abutments

Standard solutions are used much more often and can reduce the cost of restoration, and this trend will continue in the near future. However, we will deal with statistics and forecasts at the end of the article.

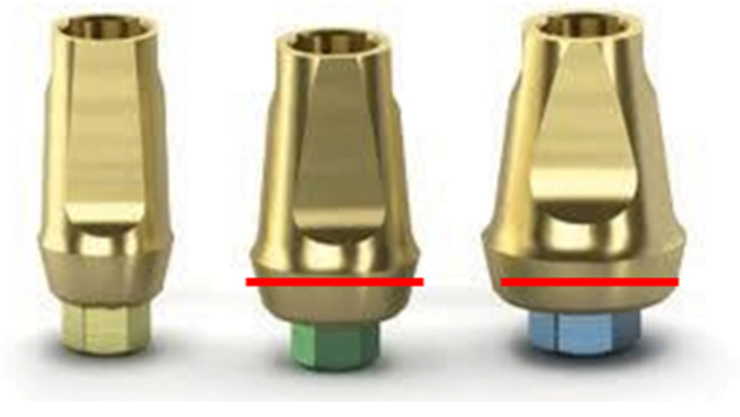

Abutments for cementation

This is the most common type of standard abutment today. There are straight and angled abutments that can successfully solve most clinical cases. Standard abutments are finalized by the dental technician to obtain the most suitable base for fixing the prosthesis. Recall that only the supragingival part of the abutment is processed, the interface and everything below the red line in the picture below cannot be touched.

A standard abutment can be adjusted to the desired dimensions within a fairly wide range, but there are limitations:

- The part of the abutment on which the gum should rest does not change in any way, which is important for prostheses in the aesthetic zone.

- After processing a standard product, a 4-5 mm rod may remain, on which a crown must be installed.

This is a problem if you need to install a molar prosthesis with an area of 20 mm2 on it. In this zone, the load on the restoration is the greatest. If the body of the abutment is insufficient, then it is only a matter of time before the unwinding and/or breakage of the screw.

This is a problem if you need to install a molar prosthesis with an area of 20 mm2 on it. In this zone, the load on the restoration is the greatest. If the body of the abutment is insufficient, then it is only a matter of time before the unwinding and/or breakage of the screw.

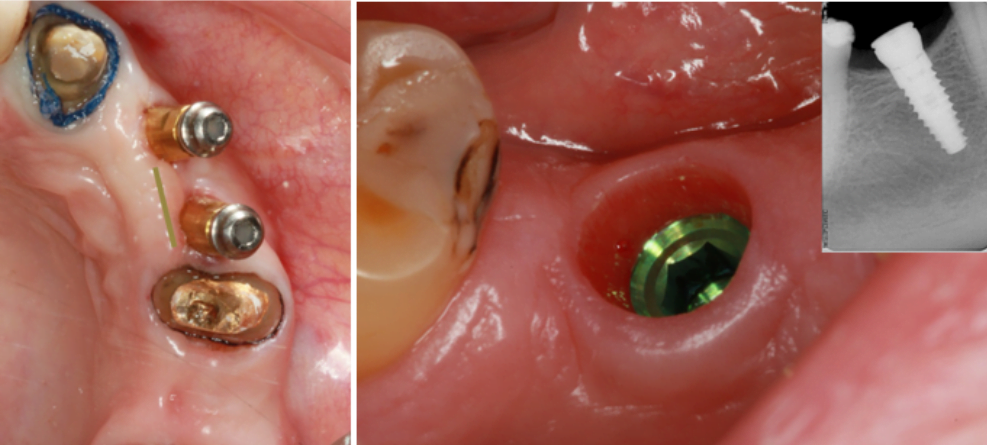

Nevertheless, if you combine straight and angled abutments plus refine them in place, you can get a very high-quality restoration in every sense, see an example of a cement-retained metal-ceramic restoration below.

Standard cement-retained solutions are a good option to reduce the cost of restoration, although many operations and manipulations in the patient’s oral cavity are required, which is a significant discomfort.

Abutments for screw retention

This option solves several problems of the previous option.

Firstly, most of the processing and fitting of the prosthesis, and most importantly, all operations with cement, are performed outside the patient’s oral cavity.

Secondly, it simplifies the task if you need to remove the restoration for replacement, repair or maintenance. To do this, drill holes opposite the screw shafts. Unscrew all screws and remove the restoration. In the case of cement fixation, the restoration would have to be destroyed, which is difficult and traumatic for the patient.

There are two basic types of standard screw-retained solutions:

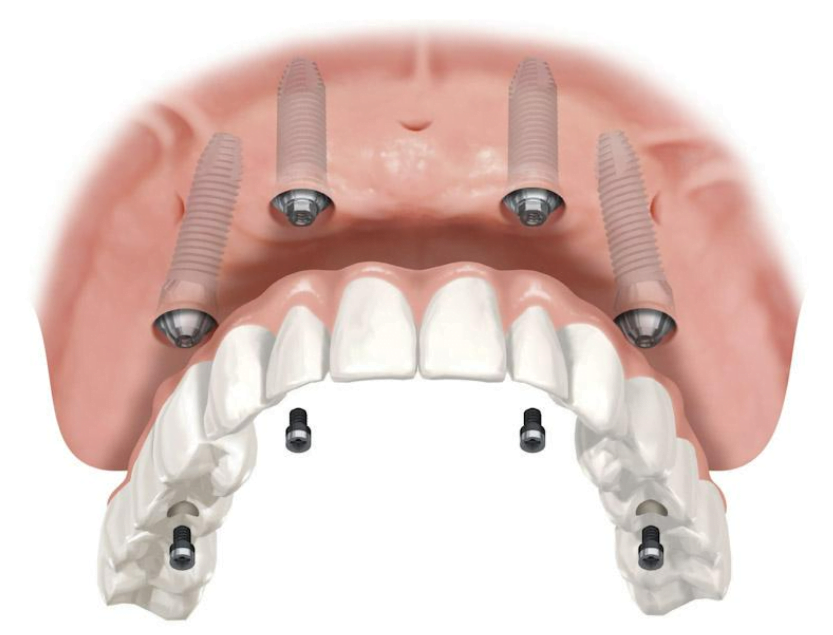

- Multi-Unit Abutments for group restorations, including for full restoration of the dentition according to the protocol “All on 4®” or “All on 6®”. There are both straight and angled multi-unit abutments, see the illustration below.

As for the interface, you can most often buy multi-unit abutments for internal hex or for conical connection with platform switching at 11°. Such abutments are installed in the implant immediately, and all other manipulations, such as taking an impression and measurements, are done from the level of the abutment. Multi-unit abutments must not be turned or reworked in any way. The head of the abutment has a shape exactly corresponding to the titanium sleeve of the conical shape, which is fixed in the prosthesis, and then the finished restoration is installed on the abutment and screwed. The screw shafts are closed according to the same protocol as fillings in the treatment of caries.

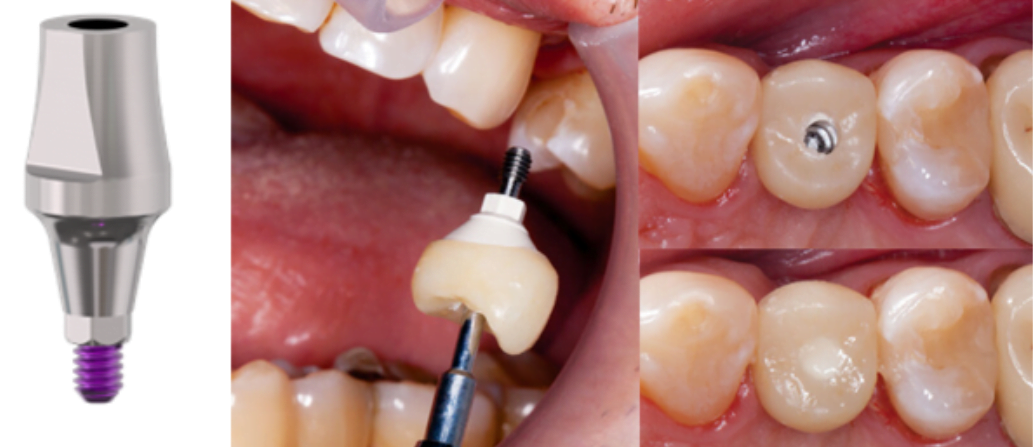

Multi-unit abutments cannot be used for single restorations because the titanium sleeve is round and the risk of crown rotation is too great under masticatory loads. The price of a multi-unit abutment is significantly higher than abutments for single fixations. - T-base screw-retained abutments are specifically designed for single restorations. There is no sleeve, which is separately fixed in the prosthesis, the crown is immediately formed on the abutment and installed in the implant, see the illustration below.

T-base abutments have different sizes and configurations, but they always have grooves or anti-rotation cuts, which eliminate the risk of the crown turning relative to the base. The possibility of fitting and refining such structures to the individual characteristics of patients is limited.

T-base abutments have different sizes and configurations, but they always have grooves or anti-rotation cuts, which eliminate the risk of the crown turning relative to the base. The possibility of fitting and refining such structures to the individual characteristics of patients is limited.

Based on the foregoing, cemented abutments have more opportunities to adjust the fastening of the prosthesis to the anatomical features of the patient.

Features and manufacturing technology of individual abutments

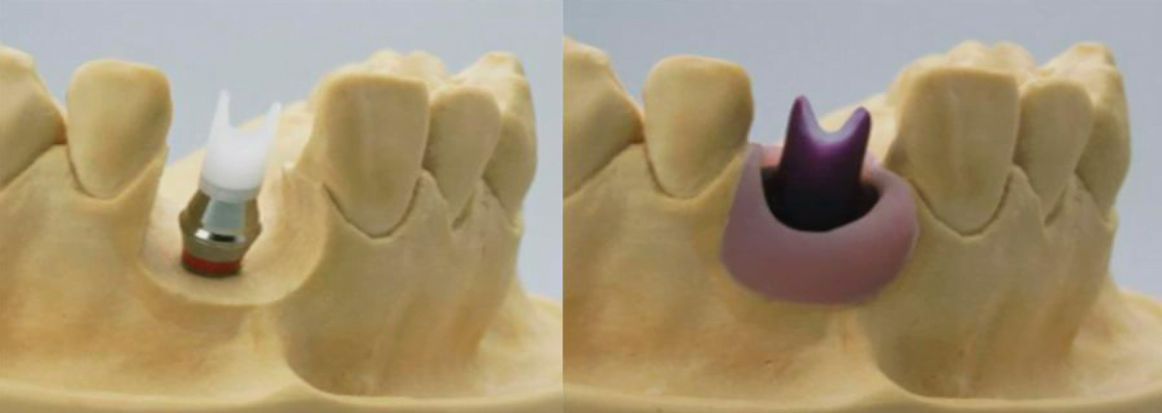

The most common type of custom abutments is castable abutments, which are made on a base of ashless plastic, see the illustration below.

Such bases allow you to make an individual abutment, both for cement and for screw fixation. It is accepted by the ITI conciliation conference that both cement and screw fixation are equivalent.

The plastic blank is cut to the desired height, and then an anatomical shape is formed around it using a special wax mixture. The resulting form is placed in a non-combustible mixture of heat-resistant clay and poured with molten metal. The wax and ashless plastic burn out without leaving any residue and the result is a metal individual abutment that is fully consistent with the clinical case.

The pictures below show a comparison of how a standard angled abutment and an individual cast solution look on the model during the manufacturing process.

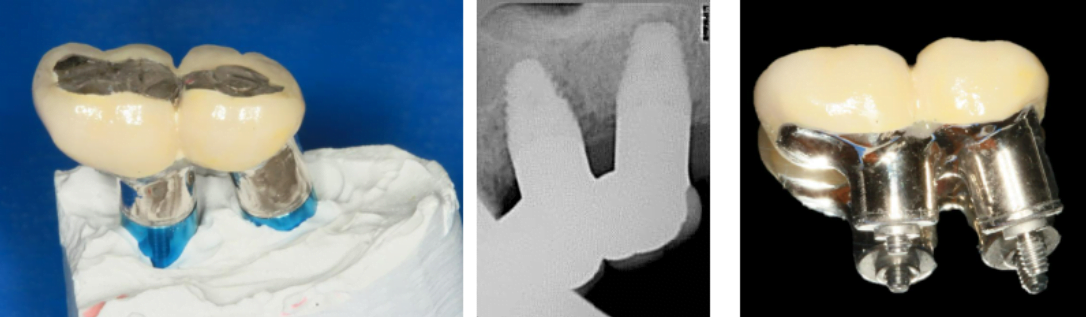

This protocol solves most problems with suboptimal implant placement. Even in the case of a group restoration, when there is a significant difference in the level of implant placement, it is possible to solve the problem with cast screw-retained abutments, see the series of images below.

What is the result – sales statistics and forecasts

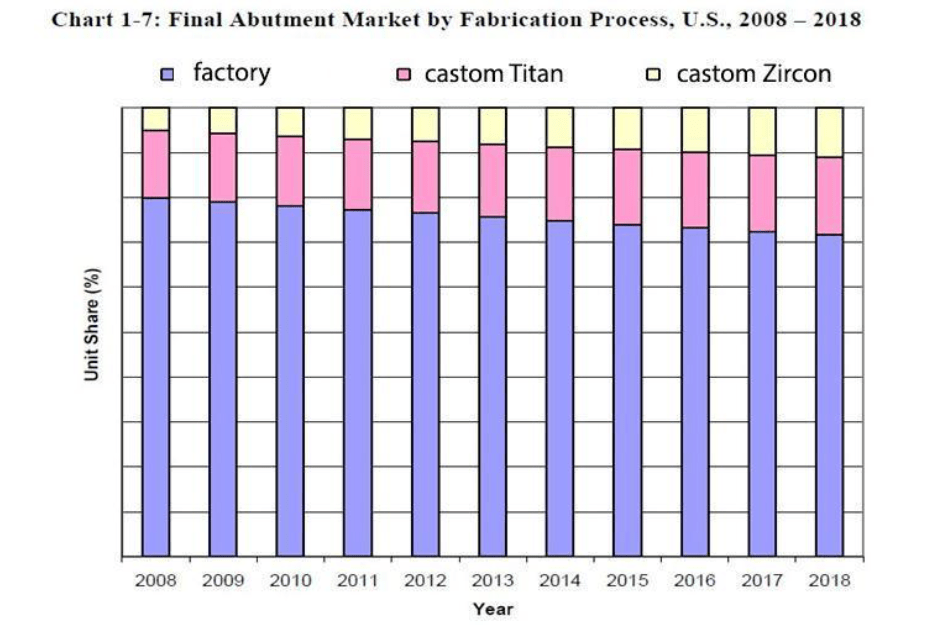

The graph below shows the dynamics of sales of individual and standard abutments, for the period from 2008 to 2018. As you can see, the share of individual solutions is growing, albeit slightly.

Standard products account for, and will continue to account, for the lion’s share of sales especially considering that the need for custom abutments is often due to inadequate quality of surgery. If the prosthetic position of the implant is correct or the deviations are minor, standard abutments are the best solution. They are cheaper, easier to handle and the quality of the restoration is in no way inferior to that made on individual abutments. Although there are a fairly large number of specialists who make individual support bases for all patients, this approach cannot be called wrong either.