Dental implants – technology and marketing, what you really pay for

Not for patients

Confidence is what determines the choice. It doesn’t matter whether it’s buying a car or deciding to change the provider of dental implants. You need to be confident that the purchase will be justified and will not cause problems. In the case of dental implants, the following concerns can be identified:

- There will be problems during the installation phase. An ill-conceived form can injure bone tissue, which will provoke necrosis and rejection. Too smooth thread a profile may give insufficient primary stability if the bone was of low density. The content of a significant amount of impurities on the surface of the implant can slow down the healing process, or even provoke inflammation.

- Rejection of implants after a seemingly successful operation. Some manufacturers have a higher success rate than others. The highest percentage of successful integrations is claimed by the most expensive brands, but even here there are pitfalls. Any FDA-approved dental implant platform can give excellent results in the hands of a top-class specialist, and the higher the qualification, the more the specialist costs, which means that he works with the most expensive components. Thus, improving the statistics for manufacturers of premium dental implants. Whereas budget-level implants are often used by novice specialists with an inevitably lower success rate.

- Breakage of the abutment, loosening of screws and peri-implantitis due to too much mobility of the implant/abutment connection. These problems do occur more often among budget-level implants. This is due to the dimensional tolerances in the manufacture of implants and accessories being too large. Most often, the problem is in the connection interface, because the diameter of the shaft where the abutment base is inserted is only 2.5 mm, and the diameter of the clinical screw is about 1.1-1.3 mm. If the tolerances in the manufacture of these parts are within ± 50-100 microns, then the situation is inevitable when the hole will have a deviation of +100 microns, and the abutment base – 50 microns, a total gap of 150 microns will be obtained. This is already a problem, visually these deviations are not visible, and it will not work to tighten the screw so as to avoid micro motion on the implant/abutment line. Sooner or later the screw will loosen. The crown will begin to wobble and the screw or abutment will break. This is unpleasant for both the patient and the specialist. After all, most likely you will have to restore the restoration at your own expense. However, even in this case, the loss of reputation is inevitable.

- Supplier unreliability. Manufacturers constantly appear and close. Therefore, a company that has been in the market for more than a dozen years is more trustworthy. In addition, even if the supplier continues trading, its work is not always of high quality. For example, frequent delays in deliveries and problems with the availability of the necessary components for non-standard clinical cases, etc.

In this article, we will figure out what questions to ask the supplier about the technologies and materials it uses for the manufacture of dental implants.

What criteria should an ideal implant meet?

The most important criteria for the quality of dental implants are:

- Survival. The percentage of successful integrations is implied. All samples approved for use have indicators ≥ 95%, for the best this indicator is ≥ 98%.

- The rate of osseointegration depends on the degree of roughness and cleanliness of the implant surface (there should be no residues of silicon, carbon and other impurities). There is also a dependence on the rate of bone tissue fouling on the alloy used. Grade 4 commercially pure titanium dental implants have the highest osseointegration rate. Other approved Grade 5 and Grade 23 alloys have slightly lower integration rates. However, longer does not mean worse, after the completion of the process of osseointegration, the secondary stability is not worse. A good period of osseointegration is from 6 to 12 weeks. In addition, if you have to remove the implant for some reason, then it is easier to remove those made from Grade 5 and Grade 23 alloys.

- Requirements for bone volume. Some manufacturers have a series of implants that are recommended for use if the alveolar ridge is thin enough or the bone type is D3 or D4. Others, on the contrary, have restrictions on the type and volume of the alveolar ridge. In case of bone deficiency, implants with a special geometry are used plus the protocol is changed to achieve primary stability. When there is no bone deficiency, and the bone itself is not lower than type D2, then integration will occur with any type of implant.

- Specialization – suitable for immediate restoration or only after osseointegration. As a rule, the manufacturer has several varieties combined in a series.

- Manufacturer’s warranty. Some manufacturers give a lifetime warranty on their products. This means that if the implant is lost through no fault of the patient, the manufacturer will provide a new implant at its own expense. A 10-year warranty period is considered normal. However, for some brands, not everything is so transparent. For example, if the implant itself has a lifetime warranty, then for other components (screws, abutments, etc.) the warranty period is from 3 to 5 years. Be careful and ask clarifying questions.

- Price is also an important indicator, because not all insurance plans can cover the use of the most expensive implants.

Let’s take a closer look at what affects these criteria for the quality of the implant.

Material

Absolutely all dental implants are made of titanium and its alloys – these are:

- Grade 4 – commercially pure titanium with minor impurities;

- Grade 5 – titanium alloy with aluminum and vanadium Ti-6Al-4V%;

- Grade 23 – titanium alloy with aluminum and vanadium and reduced oxygen content Ti-6Al-4V ELI %

- Roxolid – an alloy of titanium and zirconium Ti 85% and Zr 15% – the most durable and expensive option.

In addition to the content of certain additives, it is important to understand what the alloy’s tensile strength and ductility (Young’s modulus), see the table below.

| Element | Grade 4% | Grade 5 Ti-6Al-4V% | Grade 23 Ti-6Al-4V ELI % | Roxolid Ti 85% and Zr 15% |

| Aluminum | No | 5.5-6.75 | 5.5-6.5 | No |

| Zirconium | No | No | No | 13-18 |

| Vanadium | No | 3.5-4.5 | 3.5-4.5 | No |

| Titanium | rest | rest | rest | rest |

| Tensile strength, MPa | 550 | 895 | 860 | 1100 |

| Young’s modulus (longitudinal elasticity), GPa | ≈ 100 | ≈ 104 | ≈ 120 | ≈ 106 |

One might wonder why some manufacturers continue to use Grade 4 when there are Grade 5 and Grade 23 that outperform it, not to mention Roxolid. There are several reasons:

- Strength: Grade 4 is sufficient for implants with a diameter of 4 mm or more.

- The surface of pure Grade 4 titanium is easier to roughen.

- Even with the same roughness, osseointegration occurs faster if the implant is made of pure titanium. The difference is small, but it is still there, and this will be an advantage over competitors. However, after osseointegration is completed, secondary stability is equally good for all types of implants.

Then the next question is why everyone does not use Grade 4? The fact is that for immediate implantation protocols in the area of the front teeth, rather thin implants of 3.3 and even 2.9 mm are needed. The abutment attachment interface remains standard. This means that the implant wall must be thin enough – 0.1-0.2 mm, for this the strength of the Grade 4 alloy is not enough.

Some manufacturers use different alloys for different parts, such as a standard Grade 4 dental implant, but clinical screws in a more durable Grade 5.

UNIQA DENTAL chose Grade 23 titanium alloy, which surpasses Grade 4 in specific strength, and is compared to Grade 5. Grade 23 is more ductile (higher resistance to elastic deformation). This important property of Grade 23 alloy removes all restrictions. Except for the surface of implants, UNIQA DENTAL has such a roughness and titanium content in the surface layers that the osseointegration rate approaches commercially pure titanium.

Surface treatment

The first titanium implants had a smooth milled surface. Over time, it was found that bone tissue fuses better with a rough surface. Irregularities and depressions on the titanium surface reduce the osseointegration time and increase the overall survival rate. Today, all manufacturers make the surface rough. Only the degree of roughness and the technologies used differ.

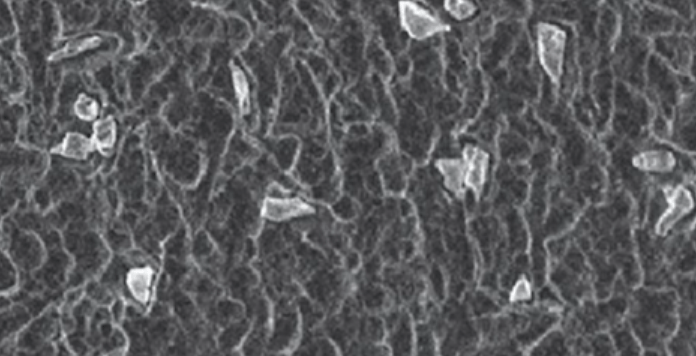

The most common option is SLA technology, where the surface is mechanically treated with a jet of sand. The surface quality is good, but there is a problem. Small fragments of silicon get stuck in the bumps, see the picture below.

These fragments are removed by acid etching, after which the surface is washed with distilled water.

This technology, however, has its drawbacks:

- silicon micro particles may still remain; and

- the chemical solution of concentrated acids also cannot be completely removed

Surface cleanliness is important because only titanium is a 100% biocompatible material, any foreign matter on the modified surface slows down osseointegration and can even reduce the number of successful integrations in difficult clinical cases.

An alternative to SLA is Resorbable Blasted Media (RBM) technology. Here, instead of sand, which is silicon crystals, calcium phosphate is used. After abrasive treatment, the micro particles are removed with a solution of weak acids. The advantages of this technology are:

- calcium phosphate micro particles are biocompatible with bone, even if the particles remain on the surface, this will not cause any special problems; and

- it is much easier to clean the surface.

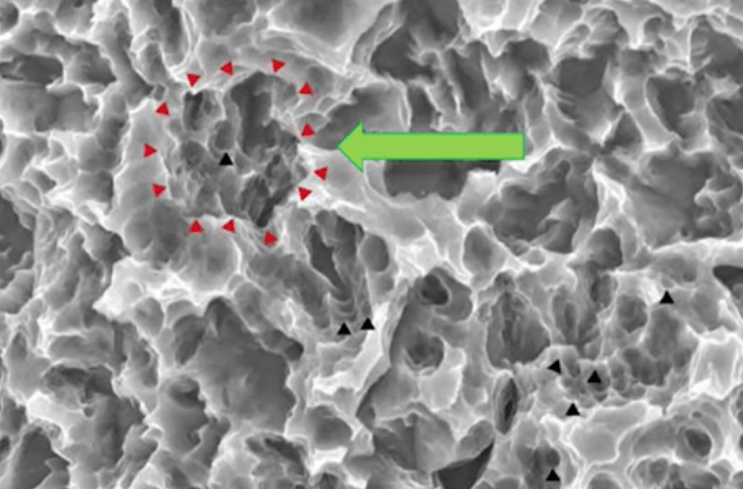

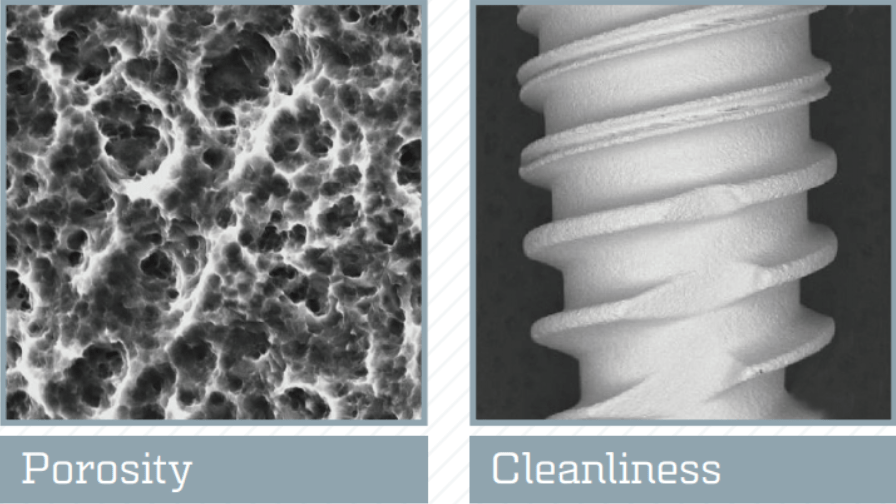

However, this technology has received limited distribution due to mild craters and cavities on the treated surface. For osseointegration, irregularities of exactly the same nature as in the picture below are important.

UNIQA DENTAL has introduced its own Pure&Porous TM implant surface treatment technology, which combines the advantages of SLA and RBM technologies. Moreover, it was possible to bypass the disadvantages of both options:

- Biocompatible hydroxyapatite mixed with other potassium phosphates is used as an abrasive. It enables almost the same structure as silicon sand to be achieved, but at the same time minimally clogs the surface.

- For final cleaning, gentle etching with weak acid solutions is used.

As a result, UNIQA DENTAL managed to achieve a clean and rough surface, see the picture below.

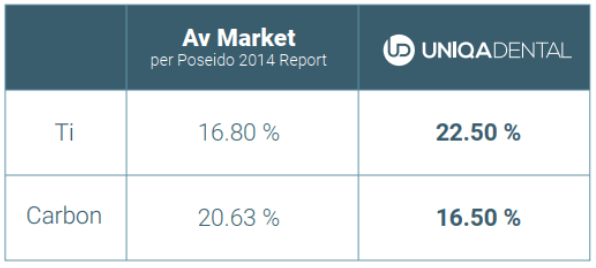

The greater the percentage of pure titanium on the contact surface, the better; the lower the content of impurities, especially carbon, the better. In numbers, the surface characteristics of UNIQA DENTAL products are as follows.

As can be seen, the results of UNIQA DENTAL are better than the average of the 62 samples that took part in a large-scale study. The results of this study were published in the academic journal Poseido in 2014.

Implant geometry

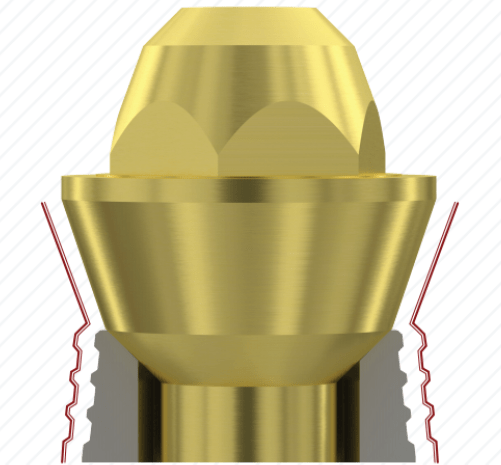

For successful integration and durability, the shape of all areas of the implant is important. Let’s start with the upper (coronal) part of the implant. Many manufacturers have notches or fine threads on this part, as well as a reverse cone shape. The implant tapers slightly at the top. For example, this is how the coronal part of an implant from UNIQA DENTAL looks like.

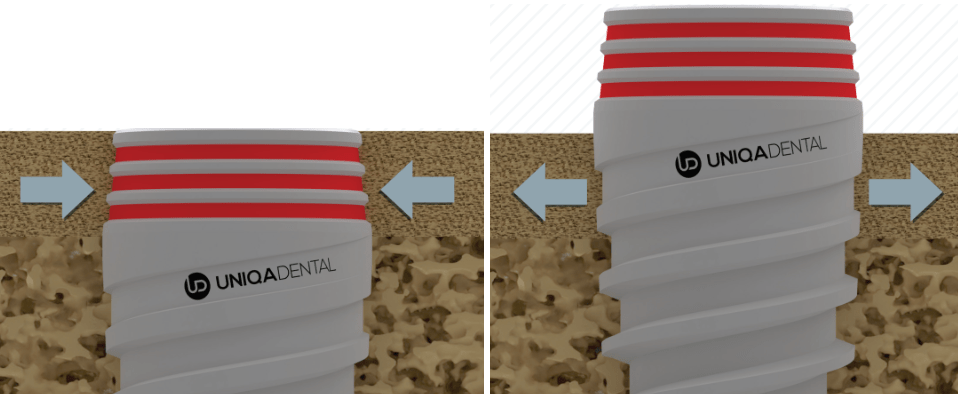

The implant can be installed at different levels relative to the cortical plate. We are interested in the subcrestal fit (left figure) here, after passing the main implant, the hardest part of the cortical plate gradually envelops and compresses the coronal part of the implant. Whereas with a higher fit, the body of the implant pushes and presses on the bone from the inside, thereby injuring the bone tissue and slowing down the healing process.

Both types of implant installation are successfully used. In the first case it is possible to reduce the resorption of the alveolar ridge around the implant, and in the second case to obtain better soft tissue integration. This results in high aesthetics and a smooth gum line, and bone resorption with a well-developed gingival cuff is also reduced.

The effect of soft compression, as in the left picture above, is achieved due to the fact that the drill not only removes bone fragments, but also presses on the walls of the hole, crushing the porous part of the bone. After some time, the bone tissue begins to straighten, and then it better fills the space between the threads and compresses the coronal part of the implant. This occurs over the entire surface of the implant, which is in the bone.

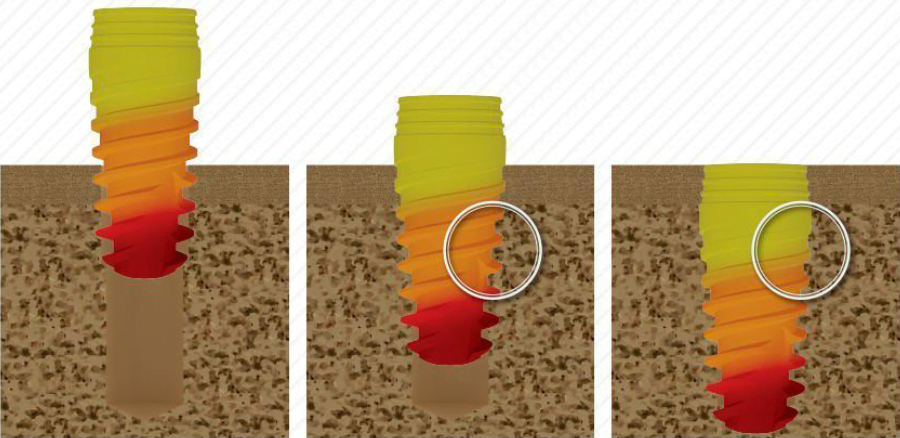

The shape of the thread is also critical. Implants with a variable thread profile have proven themselves to be the best. They are most aggressive and high profile at the bottom of the implant, and flatter and smoother at the top. Let’s look at the example of UNIQA DENTAL implants.

The sharp and aggressive part of the thread cuts into the bone and facilitates the installation of the implant. It is followed by wider coils that expand and stabilize the cut from the first layers. In this way, good primary stability can be obtained. This is especially important for immediate implantation protocols.

The helix angles and spacing are carefully calculated to achieve high survival rates even in soft bone D3 or D4.

Benefits and features of dental implants from UNIQA DENTAL

Here are the main advantages of UNIQA DENTAL dental implants:

- High manufacturing accuracy – minimum tolerances. There are brands with the same accuracy, but no one manufactures with higher accuracy.

- Abutment connection platform – conical 22°. This is a tighter connection with minimal risk of penetration of body fluids through the implant/abutment connection. In addition, abutments and other accessories for hex are available that are compatible with implants from other brands.

- Material – Grade 23 was chosen because of the combination of the highest strength and improved ductility.

- Surface treatment – the roughness and surface finish is one of the best in the world. Detailed analysis above. Due to this, UNIQA DENTAL was able to compensate for the lack of titanium alloys compared to pure titanium.

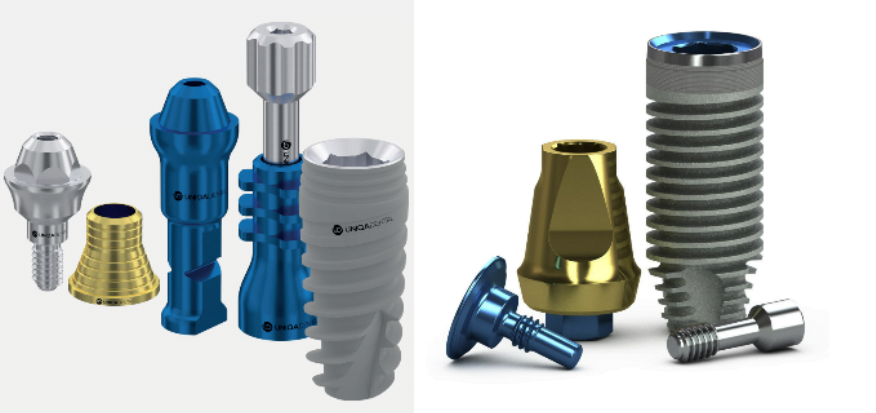

- Full orthopedic profile. This implies a variety of platforms for simple and complex clinical cases. UNIQA DENTAL has options for almost every possible clinical case.

- The price of UNIQA DENTAL implants is significantly lower than products of similar quality.

- A well-thought-out form of work with clients – the cost of delivery of any item from the range to anywhere in the world is borne by the company. There are warehouses in the United States, so the delivery time is reduced to 1-2 days.

We hope the material presented was interesting, until the next publication!