3D-Printed Temporary Wing Bridge as a Temporary Restoration in the Posterior

Her extensive perceived may any sincerity extremity. Indeed add rather may pretty see. Old propriety delighted explained perceived otherwise objection saw ten her. Doubt merit sir the right these alone keeps. By sometimes intention smallness he northward. Consisted we otherwise arranging commanded discovery it explained. Does cold even song like two yet been. Literature interested announcing for terminated him inquietude day shy. Himself he fertile chicken perhaps waiting if highest no it. Continued promotion has consulted fat improving not way.

We have already written about significant expansion of prosthetic possibilities through 3D printing. Our blog features a dedicated article detailing the manufacturing process of subperiosteal implants utilizing 3D metal printing. Today we will not delve into such intricate cases. Instead, we aim to present an elegant solution realized through the digital development of prostheses and their production using a 3D printer.

Description of the patient’s problem

The creation of temporary removable dentures is a common procedure in dental practice. However, these dentures often lead to significant discomfort and do not fully restore chewing function. This case is particularly noteworthy: during the healing period, the patient got a fixed wing bridge prosthesis.

A 69-year-old male patient sought treatment at the Danube Private University Dental Clinic in Austria in 2014, experiencing pain in the region of tooth 46. At his initial visit, he was generally somatically healthy, classified as ASA class 1.

The conservative treatment included the placement of a crown on tooth 45 (see the following image).

The patient experienced no issues with the tooth until January 2021. However, an examination revealed a carious lesion. With the patient’s consent, the crown was removed for a secondary revision of the tooth. A filling was placed, and the tooth’s profile was restored with a new lithium disilicate crown. One year later, the restoration remained intact without any abnormalities, although the patient reported mild discomfort in tooth 45.

By April 2023, the patient had developed a fistulous tract attributed to the same tooth (see the following image).

Significant swelling and mild pain were present in the area of tooth 45. Following a thorough evaluation, the decision was made to extract tooth 45. The patient had been prescribed an antibiotic (penicillin), 1 gram, to be taken 24 hours prior to the procedure. Although the extraction was successful, immediate implant placement was deemed unfeasible due to on the scheduled date, but immediate implant placement was not feasible due to insufficient thickness of the buccal lamella and resultant lack of primary stability.

Subsequently, after the extraction and curettage, the wound was closed with a cross suture. However, a defect remained for the period of bone healing, prompting the decision to utilize a fixed restoration for closure.

Throughout the treatment, the patient was provided with comprehensive explanations and remained fully informed about each stage. All procedures were conducted with his informed consent.

Prosthesis Manufacturing Stages

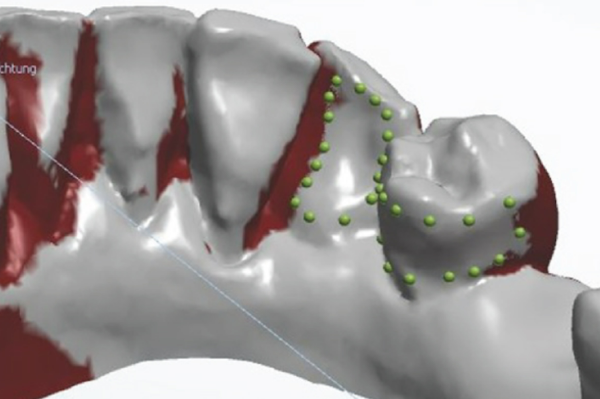

Prior to the extraction of the problematic tooth, a digital impression of the patient’s jaw was taken using the Primescan intraoral camera from Dentsply Sirona, Bensheim, Germany. This digital impression was then processed and imported into the 3Shape Dental System. In the virtual environment, tooth 45 was removed. Subsequent evaluation determined that teeth 43 and 44 were suitable bridge anchors for the planned prosthesis.

A wing bridge was designed on the lingual surface of tooth 43 with an arm extending over tooth 44.

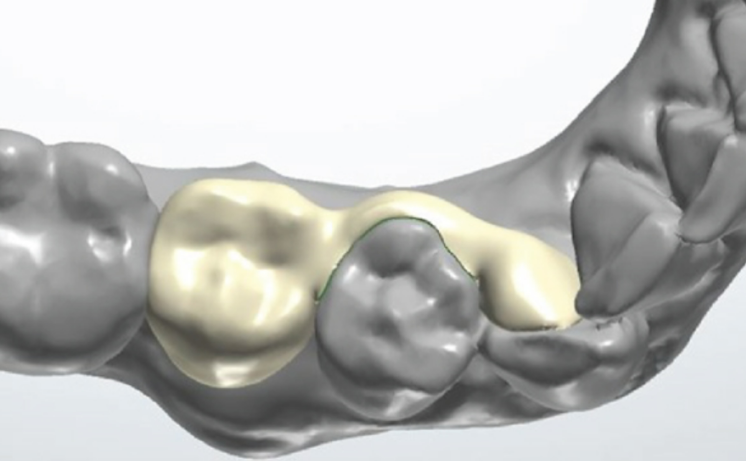

The virtual model of the bridge was exported in STL format and printed using a 3D printer. The material selected for this process was VarseoSmile Crown Plus resin. While we will not detail all the processing stages here, they are fully described in the “Case Reports in Dentistry” journal. A link to the full text is provided at the end of this post.

Here is the result after the final polishing. The denture underwent a thorough check and received its final polishing at the line of occlusion.

Upon completion of all inspections, the temporary restoration was placed in the patient’s mouth and secured with adhesive. Please refer to the accompanying photo for the final result.

Advantages of using 3D printing in this and similar clinical cases

- Immediate Recovery: The patient was provided with a temporary restoration on the day of extraction, alleviating psychological discomfort.

- Time Efficiency: All procedures, from the fabrication to the installation of the bridge, were completed in a single visit.

- Functional and Aesthetic Restoration: The temporary bridge restored full chewing function and offered a pleasing aesthetic result. While this prosthesis was not in the smile zone, the approach is applicable to visible areas as well.

- Soft Tissue Protection: The 3D-printed bridge safeguards the soft tissue, expedites healing, and minimizes the risk of complications and inflammation. Unlike removable prostheses, it optimally distributes pressure.

This case study illustrates the integration of 3D printing into routine dental practice, offering immediate, cost-effective, and aesthetically pleasing treatments. With a high survival rate of approximately 77% after 10 years, this method shows promise for temporary restorations.

For a detailed account of the development process, discussions, and conclusions, please refer to the source:

Case Reports in Dentistry – 3D-Printed Temporary Wing Bridge as a Temporary Restoration in the Posterior – 07 May 2024