Titanium. What Alloys Tooth Implants are Made of

In this article we will discuss the material used to make implants, namely titanium and its alloys that are used to make dental implants, abutments, screws and healing caps. It was the strength and biological neutrality of this material that allowed Branemark to develop and successfully introduce root implants, from which all the variety of modern dental restoration platforms have evolved.

Titanium alloys properties, differences pros and cons

There is a worldwide conventional classification of titanium by group, see the table below. All of these types are medically acceptable and the osseointegration will be successful.

The first four groups from Grade 1 to Grade 4 are considered pure titanium, while Grade 5 and Grade 23 are titanium-aluminum-vanadium alloys.

The table below shows not only the impurity content but also the strength characteristics of different types of titanium.

| The element | Grade 1 % | Grade 2 % | Grade 3 % | Grade 4 % | Grade 5 Ti-6Al-4V % | Grade 23 Ti-6Al-4V ELI % |

| Nitrogen | 0,03 | 0,03 | 0,05 | 0,05 | 0,05 | 0,04 |

| Carbon | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 |

| Hydrogen | 0,0015 | 0,0015 | 0,0015 | 0,0015 | 0,0015 | 0,0015 |

| Iron | 0,2 | 0,3 | 0,3 | 0,5 | 0,4 | 0,25 |

| Oxygen | 0,18 | 0,25 | 0,35 | 0,4 | 0,2 | 0,13 |

| Aluminum | – | – | – | – | 5,5-6,75 | 5,5-6,5 |

| Vanadium | – | – | – | – | 3,5-4,5 | 3,5-4,5 |

| Titan | остальное | остальное | остальное | остальное | остальное | остальное |

| Tensile strength, MPa | 240 | 345 | 450 | 550 | 895 | 860 |

| Young’s modulus (longitudinal elasticity), GPa | ≈ 100 | ≈ 100 | ≈ 100 | ≈ 100 | ≈ 104 | ≈ 120 |

Tensile strength tests are carried out on a special machine, which gradually increases the tensile load and records the value of the force at the moment of part failure.

What alloys are used for dental implants

For dental prostheses, three varieties are the most interesting:

- Grade 4 (conditionally pure titanium);

- Grade 5 alloy;

- Grade 23 alloy.

The last two varieties are alloys of titanium with aluminum and vanadium. They are quite close in properties, especially if you look at another marking option: TI6AL4V and Ti6Al4V ELI (ExtraLowInterstitial – super clean).

Grade 23 titanium alloy differs not only in lower oxygen, iron and nitrogen content, but in better ductility and fracture toughness. What is important for the manufacture of thin-walled implants, as well as screws for abutments, both for cement fixation and for screw fixation of the prosthesis (Multi Unit).

But ductility and ductility are the weak point of the entire group of titanium alloys, they are very strong, but when the load exceeds the limit, the titanium part will not bend or stretch – it immediately breaks. If we compare even the most ductile Grade 23 with Co-Cr (Wironit), a cobalt and chromium alloy well known to implantologists, we will see that its Young’s modulus is almost twice as high with comparable tensile strength, see the table below.

| Alloy | Young’s modulus (longitudinal elasticity), GPa | Tensile strength, MPa | Density, g/cm3 | Relative extension, % |

| Grade 23 | 225 | 860 | 4,5 | 12 |

| Co-Cr (Wironit) | 120 | 900 | 8,2 | 10 |

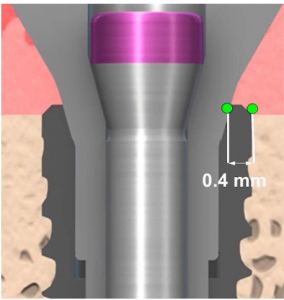

Therefore, even a not so significant difference in plasticity in favor of Grade 23 makes a significant difference. Especially when you want to make an implant with a small diameter, because the diameter of the screw or abutment remains standard and the wall thickness of the implant decreases. Type 4 titanium cannot be used for implants with a wall thickness less than 0.5 mm, anything thinner is type 5 and preferably type 23 titanium alloy.

Despite the obvious strength advantages of Grade 5 and Grade 23 alloys, no material is perfect, or else the development and testing of new combinations would have stopped long ago. At the very least, superhard alloys are more difficult to machine. But before going into detail about the properties of the different titanium alloy variants, let’s remember that Grade 4 is quite good in basic terms. The only exceptions are screws and other thin parts operating under heavy loads.

Historically, most dental implants made in Europe are made of commercially pure Grade 4 titanium. Branemark himself started with Type 1 and Type 2, so gradually everyone switched to Type 4.

The fourth type Grade 4 itself is subdivided into plain and cold-rolled G4 titanium. The rolled version has improved strength characteristics of 650-680 MPa, compared to 550 MPa for the classic version.

Most Korean manufacturers also use Grade 4 cold-rolled alloy. It is worth noting that quite often the implant body is made of Grade 4 alloy, while screws, abutments and some other thin but load-bearing parts are made of Grade 5, or TAN (titanium, aluminum, niobium) alloys. This alloy will not be discussed in detail, because only screws and other small parts are made of it.

American implantologists also initially used Grade 4, but in recent decades have completely switched to Grade 5. As for Israel, some manufacturers use Grade 5 and some use Grade 23. Our company UNIQUA DENTAL also uses Grade 23 (Ti6Al4V ELI).

We can’t forget to mention the alloy (Roxolid 85Ti 15Zr). The strength of this alloy is noticeably higher even at Grade 5 – 1000 MPa, compared to 895 MPa. It is a good and promising material, but the price of implants made of it is much higher. It is produced and used by only one company, and the description of its properties and application requires a separate article.

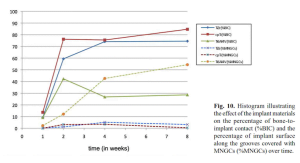

Why modern implants have a rough surface

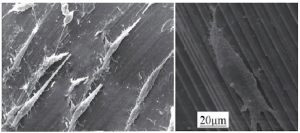

The first Branemark implants had a milled surface, which visually appears smooth and even polished. But this is not the case, the milled surface has a roughness within 0.5 microns. The milled surface of implants was practically the only option until the late 90s. And they have acclimated perfectly, the only difference is the timing and the degree of secondary stability.

But today most doctors work with implants with a machined roughened surface:

- minimally roughened 0.5-1 microns;

- medium rough 1-2 microns – this is the gold standard that most dentists use;

- coarsely roughened 2-3 microns.

The roughened surface reduced osseointegration time, and improved overall implant survival rates compared to the milled surface. A little further on, we will discuss why the modified surface gives better results; for now, let’s look at the processing technique.

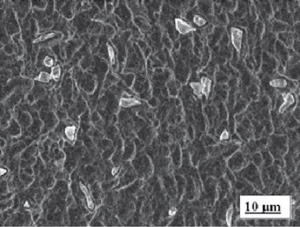

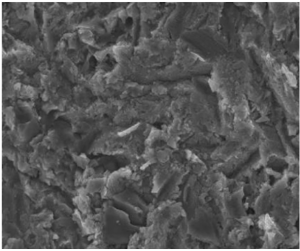

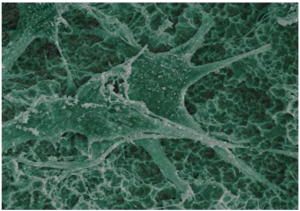

In recent years, only the extractive method of surface treatment has been used, most commonly sandblasting and acid etching to remove sand particles. The titanium particles are carried away and create pits and bumps that provide the roughness. The result is a surface that is clearly visible under the microscope in the photo above.

Previously, in parallel with the abrasive, an additive method of surface modification was also used. This is when the milled surface was covered with various substances, for example, titanium oxide or hydroxyapatite. We will not dwell on this, since they showed worse results compared to the extractively modified surface.

If we take a closer look at the most popular methods of surface modification, it turns out that the simplest and most popular is the SLA sandblasting method.

The abrasive used is aluminum oxide sand, which is hard enough to quickly create irregularities on the surface of titanium. But after sanding, quite a large number of aluminum oxide particles are trapped in the irregularities, see the microscope image below. It is not possible to wash off these particles even under pressure.

In the early days of technology, implants were placed without removing these particles, but it was found that osseointegration slows down. So it is necessary to remove these particles completely and the most effective way is to dissolve them in acid.

Acids are used to dissolve the aluminum oxide portion:

- HF – hydrofluoric acid;

- HCl – hydrochloric acid;

- H2SO4 – sulfuric acid.

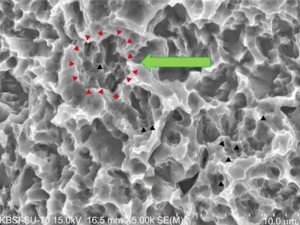

The acids are not used alone; for example, a mixture of hydrochloric and sulphuric acids works well. In addition to removing abrasive particles, the acid further expands the caverns in which the aluminum oxide particles are stuck. The degree of roughness is thereby increased, see picture below.

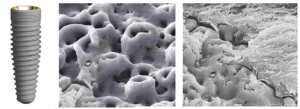

In addition to the most popular SLA technology, there are other methods, such as surface treatment with titanium oxide particles, after which acid etching is not required, see the picture of the surface treated with titanium oxide.

But many manufacturers go further and try to make the implant surface biologically active.

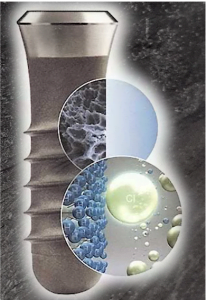

This includes fluoride treatment, which helps the surface to more easily attach calcium ions to the surface, and storing the implants in an isotonic sodium chloride solution. The latter technology is called SLA-Active.

The point of this procedure is to prevent the formation of a thin film of titanium oxide on the implant surface, which impairs wettability. After all, titanium oxide has hydrophobic properties. It is not critical, but such a film slows down the processes of cell attachment on the titanium surface.

Another interesting way to modify the surface is anodizing. Electrochemical reactions result in a very interesting surface, see pictures below.

This is an excellent base for osseointegration with fairly deep caverns and smooth transitions.

How implants from different types of titanium alloys take root and why strength is not the only selection criterion

Now let’s move on to the biological aspects of implant engraftment. We will discuss both the different degrees of surface treatment and the difference in the body’s response to different alloys.

We start by comparing the integration of implants with milled and roughened surfaces. As we have already mentioned, they take root almost equally well, but the roughened ones are faster. And if you suddenly need to unscrew the implant from the bone, you will have to make fundamentally different efforts.

- The milled implant can be screwed out with a torque of 120-160 N/cm;

- The roughened implant can be screwed out with at least 250-300 N/cm torque.

As we can see, the secondary stability of an implant with a rough surface is, on average, twice as high as that of a smooth (milled) implant. And this is confirmed histologically. Fibroblasts and osteoblasts on the milled surface have an elongated spindle shape.

At the same time, if we look through an electron microscope at the SLA-treated surface, we see a star-shaped osteoblasts, which means that there are more contact points, which is confirmed by practice.

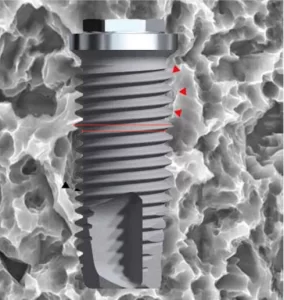

Also, the difference in integration strength is determined by the bone-to-implant contact index – BIC (Bone Implant Contact). The bone-to-implant contact ratio BIC is equal to the implant-to-cortical bone contact length (dashed line in the illustration below) divided by the length of the implant in the cortical bone.

If the surface is rough, the bone-to-implant contact coefficient is significantly closer to one (or 100%). And the closer the BIC is to unity, the better the secondary stability.

But all the above referred to the comparison of the smooth and rough surface of titanium type 4.

Now let’s look at how Grade 5 and Grade 23 alloys behave

The first problem is machining. If you sandblast a Grade 23 or Grade 5 implant the same way, you get a fundamentally different type of surface.

They are much stronger and harder and the degree of roughness is much lower.

The second problem is chemical processing. Unlike commercially pure Grade 4 titanium, Grade 5 and Grade 23 contain significant amounts of aluminum and vanadium. The implant surface reacts differently with acids. Without going into detail, the speed and quality of osseointegration deteriorates.

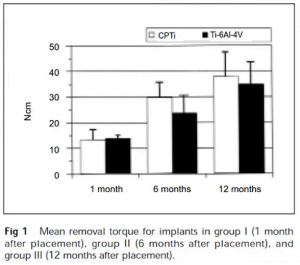

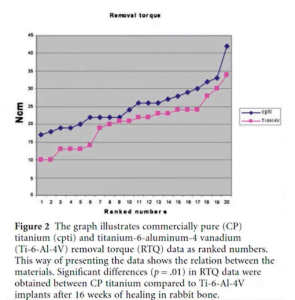

In addition to changes in surface quality, there is evidence that the titanium-aluminum-vanadium alloy itself gives worse torque compared to pure titanium. This is confirmed by the studies, the results of which we will use. Here is the first of them.

Milled implants made of pure titanium and Grade 5 alloy were used for the experiments. The diagram below shows that the unscrewing force of the implant from the bone is higher with pure titanium.

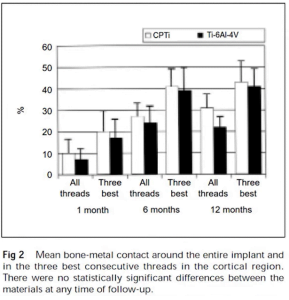

Also, histological studies showed that bone contact with the implant was markedly better with pure titanium, see diagram below.

The second qualitative work on this issue was done in 2012.

Implants made of pure titanium, cold-rolled titanium, zirconium alloy, type 5 alloy and several others were compared here, see bar graph below. It shows the dependence of the implant-bone contact. As you can see, pure titanium has the highest values and the popular alloys have average values.

The experiment of the Bern group was interesting, all specimens were milled the same way, the same surface treatment (sandblasting, acid etching, gamma sterilization, washing, etc.

Implants were placed in animals, and then comparative data were obtained.

But there is one difficulty here, among other things, the result of the study was a clear understanding that the machining of titanium superalloys should be done differently. Because it was not possible to get the same surface quality in all cases, and this affected the bone-implant contact index and secondary stability.

Considering that even in this case, the Grade 5 and Grade 23 implants performed quite well, the difference would be even smaller with proper machining and obtaining the same degree of roughness.

And there is another processing method, the RBT method. It has long been actively used in the United States and Israel, and it has also become quite common in other countries.

In fact, it is a surface treatment with particles that are easily dissolved and washed out with distilled water, most often hydroxyapatite particles. Thus, the acid treatment step is excluded from the process.

This results in a medium rough surface with irregularities of the order of one micron.

The result is.

- In spite of all the nuances of the Grade 5 and Grade 23 surface treatment, the implant-bone contact index of BIC is somewhat lower compared to pure titanium. On the other hand, the difference is not significant enough to affect the quality of osseointegration and the patient’s quality of life. The important recommendation is to wait longer and load the implant after 12 weeks instead of 6-8 weeks.

- The secondary stability is slightly higher in pure titanium even with the same surface quality. This is confirmed by the research results.

But whether this is an advantage or a disadvantage depends on the point of view. On the one hand, the higher the secondary stability, the better. On the other hand, if the implant has to be removed for any reason, the risk of bone trauma or implant fracture is higher with a Grade 4 implant. And if you consider that in real life the implant is not even close to such stresses, then the extra high secondary torque is more of a disadvantage.

To summarize, any certified platform for dental prosthetics can be used successfully. The choice has to be made consciously, because every material and every type of treatment has its advantages and disadvantages. Research and technology do not stand still. New solutions and combinations of old ones appear. We recommend to follow the innovations and implement those elements that have proven their effectiveness in practice.

-

Zimmer Biomet® Compatible Screw Retained Restoration Trial Kit + Dental Implant

Original price was: $134.$9.90Current price is: $9.90. Buy Now -

Zimmer Biomet® Compatible Screw Retained Restoration Trial Kit

Original price was: $70.$0.99Current price is: $0.99. Buy Now -

Zimmer Biomet® Compatible Cemented Restoration Trial Kit + Dental Implant

Original price was: $114.$9.90Current price is: $9.90. Buy Now -

Zimmer Biomet® Compatible Cemented Restoration Trial Kit

Original price was: $50.$0.99Current price is: $0.99. Buy Now